Used to seal food, beverages and aerosols, semi-automatic can seamers see a lot of action in Vietnam-the Southeast-Asia based country is home to many such machines. These machines are an essential component of ensuring the high level and freshness of products, which greatly impacts global logistics. For the five-part series, we are going to jump into some common Vietnamese brands that have become a household name and one of those ones from Revelation Craft Brewing Company has been semi-automatic double seamerA while ago but strap in today.

Vietnam Can Seamer Fabricator

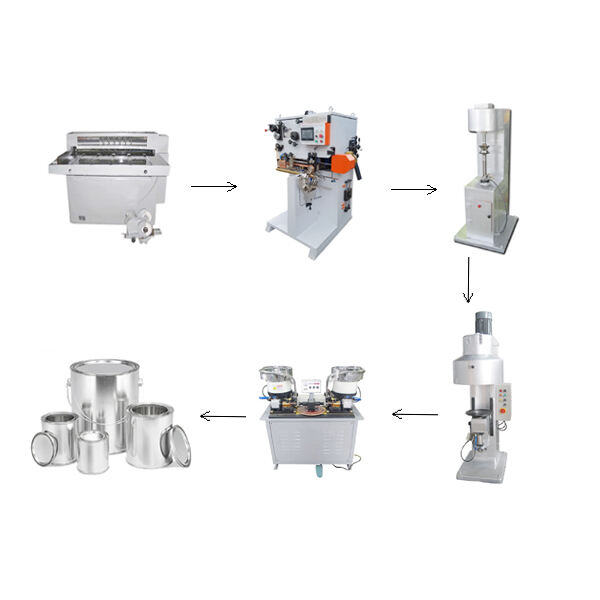

The market for can seaming technology in Vietnam is a mix of conventional work and high-tech. These companies established the market, using precision-engineering to create machines that should last as long as they are meant to. High quality seamers can be designed that will reduce costs, achieve the necessary setups for production on a partial run or with modifications between batches.

Machines that are new from Can Seaming Vietnam Industry

Currently, in the Vietnamese forklift industry is popularizing sustainability and efficiency standards are new trends unobtainium massively to manufacturing factories were all forklift manufacturers develop their products. Both The Bradbury Group and Knudson have made their seamers smarter - more adaptable to the needs of today's manufacturing plants - by adding high-level PLC controls on large motors. Facilitating post-purchase enhancement supports the objectives of Industry 4.0 as well, and together with IoT-enabled features also paves way for a smart factory future

Vietnam Can Seamer Manufacturers

Dong Anh Packaging Machinery (DAPM): Buying the DAPM machinery can seaming devices, you are getting an economic option that offers efficiency at its best. Their machines do have tech sheets in them everything of course, but what really sets our quick changeover that gives flexibility for the customer operations.

VietSeamer Technologies: A precision engineering that helps a large enterprise to implement customized packing solutions. They are one of the fastest and most reliable can seaming solutions available for processing companies looking to reduce downtime and maintenance costs.

Hanoi CanTech is the forerunner in establishing AI to manage seaming quality and guarantees that seam empty + air-tight on all canned ends packed from our lines. Finally, an on-top model is made by the HERS Rater to represent all possible what-if scenarios of that AS-Determined buildingThis technology focused approach avoids human errors and makes warehouses better functioning as well as profitable.

Honda Thanh Long: A lineup of cars offers a powertrain that combines performance and environmental sensitivity. Their technology is built to last and created with the next common production lines that are capable of diminishing carbon emission.

Nam An Seaming Solutions: Nam AN is one of the first providers engaged in canning, and so its technology has been increasingly perfected by their R&D department over time. This ensures that easy and lean operation such as troubleshooting assistance, regular maintenance etc. is provided ensuring quicker issue resolution during production with minimum downtime 7.

New Horizons for Vietnam Can Seaming Industry

The best and toughest manufacturers today are no longer manufacturing equipment, but making trend signal. Finally, our Customers now leverage smart technology to offer real-time monitoring and predictive maintenance service - based on data driven decisions which results in great work output while reduce downtime / occupational cost. Ground-breaking can seaming solutions from Vietnam are helping the industry advance into a new age of innovation and quality, with bespoke in eco-friendly options.

MACHINES AND TOOLS CORP - BEST CAN SEALING MANUFACTURER IN VIETNAM

This is because they were looking after their customers and kept innovating. Firstly, these manufacturers of course need to implement post-sales support and training initiatives or their customers would not be able to realise any value from what they spend. This commitment to service excellence is the building block of robust partnerships and customer relationships, continuously powering General Practice improvements and innovation.

To summarize, the Vietnamese can seamer manufacturer is in effect leading global trends through innovation and sustainability while ushering a new standard of performance with respect to fractional volume rotary sealing technology by rendering an unparalleled level customer service. As global demand for these new solutions has started to rise, the second generation with leading packaging producers in Vietnam are being groomed as leaders of this important change that can finally drive a stagnant industry forward and gain efficiency along performance.

EN

EN

AR

AR

FR

FR

EL

EL

HI

HI

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

BN

BN