The semi auto tin can top and bottom making line is suitable to match our semi auto canbody making line,production

capacity is 15-20 cans per min.

We supplied our tin can top and bottom machines to Saudi Arabia, Dubai, Vietnam, Malaysia, India, Mexico, Jordan and so

on.

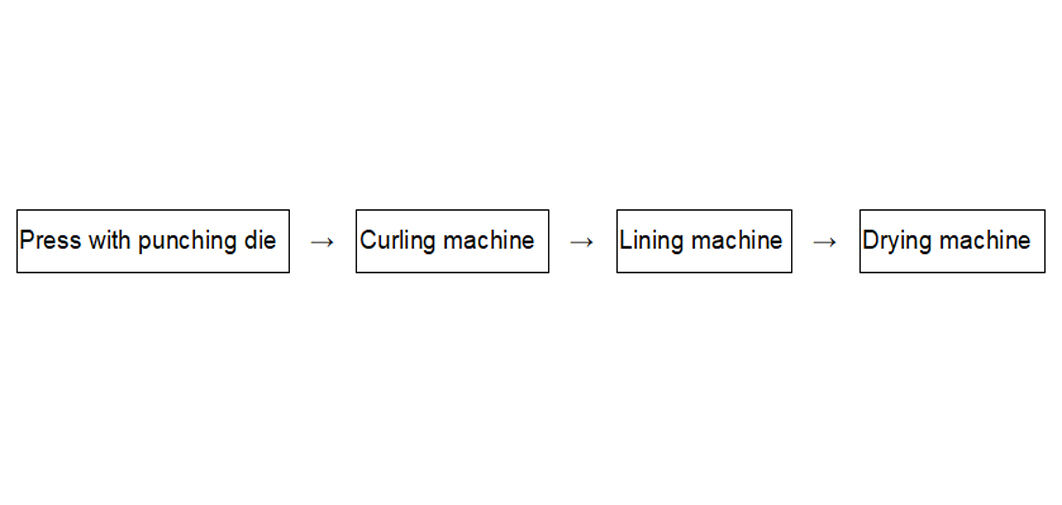

Layout of semi auto tin can top and bottom making line

Machine Details of semi auto tin can top and bottom making line

1. Press

| Model | J23-16 | J23-25 | J23-40 |

| Norminal force(kN): | 160 | 250 | 400 |

| SPM(min-1): | 125 | 60 | 55 |

| Between slide center and frame: | 160mm | 210mm | 260mm |

| Shank hole(mm): | Φ40*60 | Φ40*70 | Φ50*70 |

| Motor power(kw): | 1.5 | 2.2 | 4 |

| Net weight(kg): | 1080 | 1900 | 3180 |

2. Punching Die

| Shape: | Round/Rectangular/Square |

| Material: | Cr12mov/D2/DC53 |

| Applicative Diameter(mm): | Φ52-Φ180 Φ220-Φ300 |

| Net weight: | 100-200kgs |

| Dimension: | 200x200x80mm |

3. Semi-automatic Curling Machine

| Model | GT2B3 | GT2B5 | GT2B8 |

| Capacity(pcs per min): | 30-100 | ||

| Applicative Diameter(mm): | Φ52-Φ108 | Φ108-Φ153 | Φ153-Φ180 |

| Power: | 0.5kw | ||

| Net weight: | 150kgs | ||

| Dimension: | 740x1100x590mm | ||

4. Semi-automatic Small Round Can Top&Bottom Lining Machine

| Model | GT2C3 | GT2C5 | GT2C8 |

| Capacity(pcs per min): | 30-100 | ||

| Applicative Diameter(mm): | Φ52-Φ108 | Φ108-Φ153 | Φ153-Φ180 |

| Power: | 1kw | ||

| Net weight: | 150kgs | ||

| Dimension: | 740x590x1100mm | ||

5. Semi-automatic Conipail Top&Bottom Lining machine

| Model: | GT2C18 |

| Capacity: | 15-20pcs/min |

| Thickness: | ≤0.4mm |

| Diameter: | 10L-25L |

| Height: | 270-400mm |

| Power: | 1.5kw |

| Net Weight: | 150kgs |

| Dimension: | 1400*720*1400mm |

6. Semi-automatic Drying Machine

| Model: | GT2D5 |

| Capacity: | 15-50cans/min |

| Thickness: | ≤0.4mm |

| Applicative Diameter: | Φ52-Φ180 Φ220-Φ300 |

| Power: | 15kw |

| Net Weight: | 500kgs |

| Dimension: | 5000x700x1800mm |

Our friendly team would love to hear from you!

Our professional sales team are waiting for your consultation.