Today, a tin can is the important vessel we use for keeping and selling food products. Drive into the technological aspect and how it affects tin can output.

The tin can, once predominantly made of metal was heavily infusioned with computing to produce this age-old fabrication. Not only this though - it is also a step forward in the way technology can provide, as it has speeded up productivity but without reducing efficiency. Robots are utilized that have improved this production process of the classic tin can packaging even faster.

In the past, production tin tanks were only able to output dozens of cansper hour due to traditional equipment in wine processing units. Nevertheless, with the advent of new technologies this process was modernized considerably and production capability also soared up. Robots, aided by automation become a vital cog in This helps to speed up the production line and also help minimize operational costs for seamless operations.

Whilst the advancements made have sped up production and increased accuracy. State-of-the-art machines are now able to mould, coat and paint cans with unrivalled precision resulting in a high-quality end product. Not only does this save time, it also helps optimize the process by eliminating manual work such as labeling and packaging of bottles from machines into cartons.

Facing a growing crisis over environmental sustainability, the tin can industry is turning itself in new green directions. However, a growing number of manufacturers are turning to more parts that help reduce environmental load such as energy-efficient engines and waste reduction strategies as well incorporate recycled materials. Not only are these environmental efforts changing the face of tin can manufacturing but they also integrate with a global trend towards greater corporate social responsibility.

Not only that, the fact that tin cans are so much needed in a plethora of sizes and shapes across multiple industries has caused manufacturers to come up with innovative designs. New flexible machines designed to swap molds with as nearly no downtime exist for what amounts, essentially, customers desire. The seamers, welders and coating machines have been designed to help can manufacturers produce individualized cans that meet the specifications of their customers.

Manufacturers Understand the Important Role Small Businesses Play in The Tin Can Industry, Offering Cost-Effective Solutions to Serve Their Operational Needs These affordable machines help small business owners work more efficiently, increase productivity and improve quality. Small businesses can deploy this from semi-automated to fully automated systems, use it and feed on them in such difficult times are the gateway for their profitability as well a competitor in the market.

This is in addition to what promises to be a revolutionary transformation of the landscape of aluminum tin can production, with sustainability initiatives being implemented like never before. This blend of many years series connections in automation reliably allows to produce as well ecologically sound and high-grade products. As it turns out, the evolution of tin can manufacturing represents both innovation and a path to sustainability in its own right - one that extends far beyond this particular sector.

In the other words, This is just showing 20th-century technology and sustainability working hand in hand to produce tin cans. As this evolution has progressed, it provided a new rapid design to create an interconnected eco kind of the tin can which is environmentally friendly and accessible as well all while delivering high-quality production to a previously unsustainable industry.

In the pre-modern past, machines such as a tin can machine could only have produced thousands of cans within one hour. New technology has been put into these machines to simplify the process of manufacturing cans which means a faster turnaround time can be delivered. The entire production process is time- and cost-efficient through automation of material handling, Feeding & Can filling.

The debut of automation in the tin can packing machines factory has proven to be life changing for production. Thus, automation has facilitated in better accuracy and is more faster & cost-effective manufacturing of cans. Those high-tech machines are capable of shaping, coating and painting cans with unsurpassed precision. The packaging process has been additionally hastened by advanced machinery as automated labeling, and packing machines get the job done significantly faster with much more efficiency.

With the rising concern for protecting and preserving our environment, the tin can industry is placing its attention on practices centred around a greater care of & responsibility towards mother earth. Here, manufacturers prefer using eco-friendly processes and materials with less environmental impact. Energy-efficient engines, low levels of waste while using the tin can machines and opportunities for re-use cans as well as several other materials are standard specifications in this type of tool. These advances in tin can manufacturing have opened up the doors for a green approach.

However, it - and any canning machine for that matter - can be used to process other types of tin as well.

Different industries need a different shape and size of tin cans to fulfill their requirements. Tin can machine manufacturers have also come up with inventive designs that are making this possible. The molds of today's machines can be easily interchanged, so that cans in different shapes and sizes are manufactured with no difficulty. Seamers, welders and coating- or painting machines additionally help manufacturers to provide high-quality products that meet the requirements of customers.

Manufacturers have made it a point to provide cost effective solutions that cater for the needs of small businesses which remain major players in tin can industry. There are a number of tin can machine options now available which meet these requirements and have proven to be incredibly affordable as well. These innovative solutions enable small businesses to invest in high caliber machines that boost efficiencies, improve productivity and quality as well as drive profitability. For small business owners, whether they go for semi-automated or even completely automated machines entirely depends on their budget and output requirements.

In conclusion, the advancement of technology and emphasis on sustainability have driven the tin can industry into a new era. The result: a highly networked, fast-speed automated model that is eco-friendly and making an affordable machine available to smaller businesses for tin cans produces high-quality products meeting the needs of customers as well as preserving our planet.

We have a skilled team that can offer after-sales services to tin can machine and use their machines properly.

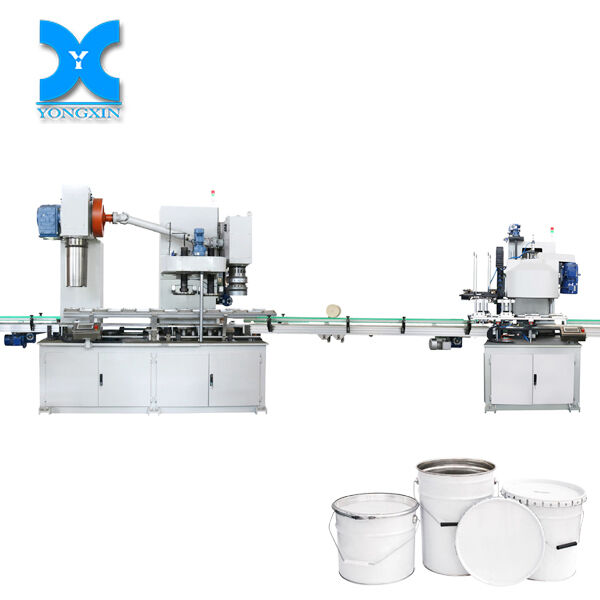

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd has been tin can machine and production of tin can equipment. We have high-speed automated equipment, like the general small round 40/60cpm can line; 30/50cpm rectangle small can line; 30cpm pail can machine line and 30cpm square big can line. Our products are shipped not just to the local market, but additionally to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with a wealth of experience. We offer cutting-edge technology, high-quality can machines as well as excellent after-sales service. We, Jiujiang Yongxin can equipment Co., Ltd will be your best choice for making cans with our machines.

With more than 20 years experience in tin can machine Jiujiang Yongxin Can Equipment specializes in can-making machines. We offer all kinds of can-making machines, both semiautomatic and automated. They offer top quality and excellent service. Can sizes range from 0.1L-25L in round and square cans for paint, food and general use. With great after sales support and a stable running condition, Yongxin can making machine has earned the trust of can makers. With years of investigation in the field, we've come up with an automatic UN Pail line. Closed drum making line. Check out our website for more details on making cans.

We are JIUJIANG YONGXIN CAN Equipment CO., LTD has been accredited by CE certification, SGS testing and tin can machine, for the products of automatic can seaming machine, automated round and square can body-making machines. We also have more than 84 patents, like for automatic small rectangular can body making machines, for an automatic round and rectangular can seaming machine for a paper-based can seaming machines and others, which are protected by the independent intellectual rights of property. The company was categorized as an "high technological enterprise in the province of JIANGXI Province" in China.

Our professional sales team are waiting for your consultation.