Ever wondered how some of our favorite foods such as fruits, veggies and even soups are packaged in cans? These cans are a product of tin can manufacture. This BPA lining is the most important part, which keeps our food in a safe and fresh state for a long time.

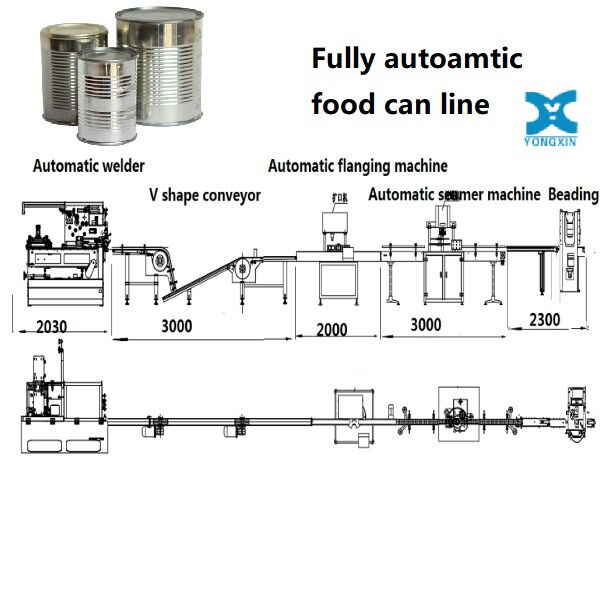

As it pertains to the tin can manufacturing process, we focus on how various forms of food and drink are sealed in their respective types of cans. The sheets turn into cans that are durable and strong. It starts with sheets of metal which are pressed, then cut and welded together to form a can. This would add more weight to the can, but manufacturers coat them inside with lacquer or other protective coating so food is never required to touch metal. YONGXIN tin can maker keeps the food from harm and allows it to be fresh for a more extended period of time.

Production of metal sheet came from materials like tin-coated steel, bare and galvanized, or aluminum which is flattened by rolling between two rollers. YONGXIN tin manufacturing machine makes metal stretch in to thin sheets with simplicity. The rolls are then cut to form the sheet -after-sheet. This form them in the shape of cans. Then the sheets are printed with different colored labels and designs that show us what is inside of the can.

The sheets are formed into cans of continuous motion rotating machines called can former. There is a lot this machine does. It cuts the sheets to fit and then punches holes for the lid. Another sheet of metal forms the lid itself. It is cut and shaped to also fit the can perfectly up top as well. The can is checked for safety after everything comes together. Workers check for any rough edges as well that the can has been shaped correctly and is safe to use by us.

Creating a tin can is not simple, it must be properly measured at each single step. A very precise set up of should be done on the YONGXIN automatic tin can making machine that are used to make cans. It means that all of the cans are identical. Skilled workers monitor the procedure and look after machines. The cans are tested in all respects so that we could not think about safety.

A number of companies nowadays are opting for aluminum cans as opposed to steel cans. Some advantages of using aluminum cans over bottles are that they are lighter and more recyclable. Aluminum cans are endlessly recyclable. They can be reused hundreds of times without losing their quality, and since we are all trying to truly save the planet its selection is incredibly important by using tin can making machine production line.

Tin works needs a team of skilled workers in order to perform cans consistently. This team consists of artists, who create the exciting labels; engineers to build tin making machinery and technicians oversee their operation while maintenance workers make sure everything runs smoothly. Between the two, they make certain the process runs properly and correctly. There is a lot of knowledge about how to make tin cans and the functions of machines, which are really needed for it all to work.

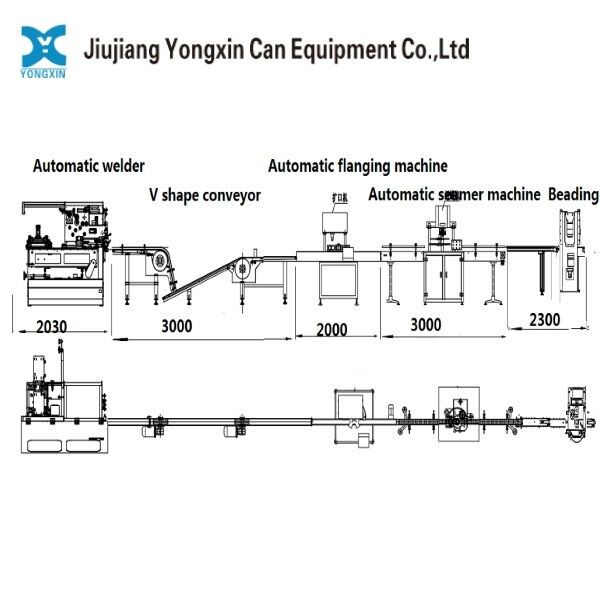

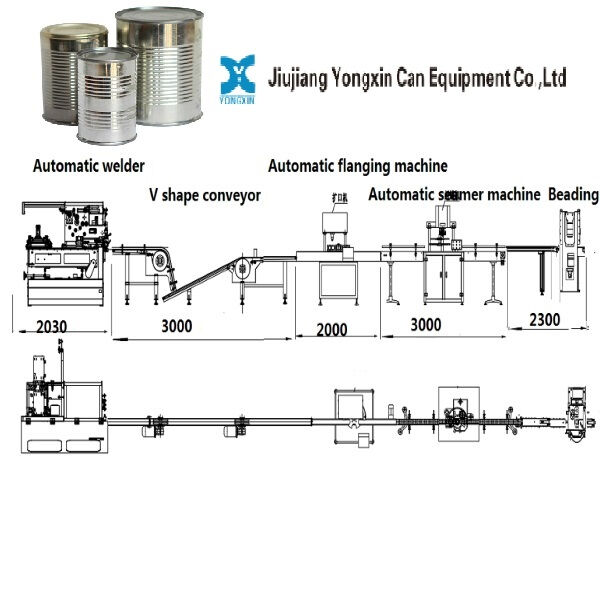

Jiujiang Yongxin Can Equipment specialized in the field of making cans machines with more than 20 years of experience in the Tin can manufacturing process. Provide all kinds of can making machine in semi-automatic and automated versions. With high quality and best service. Can sizes range from 0.1L-25L in square and round cans for paint, food and general use. With excellent after-sales service and reliable running conditions, Yongxin Can making machine has enjoyed the trust of can makers. With years of study in the field, we've come up with an automated UN Pail line. Closed drum making line. Check out our website for more details on making cans.

We are JIUJIANG YONGXIN CAN Equipment CO., LTD has been accredited by CE certification, SGS testing and Tin can manufacturing process, for the products of automatic can seaming machine, automated round and square can body-making machines. We also have more than 84 patents, like for automatic small rectangular can body making machines, for an automatic round and rectangular can seaming machine for a paper-based can seaming machines and others, which are protected by the independent intellectual rights of property. The company was categorized as an "high technological enterprise in the province of JIANGXI Province" in China.

Jiujiang Yongxin Can Equipment Co., Ltd has been dedicated to tin can machines developing and Tin can manufacturing process since 2005. We have high-speed machines, including the 40/60cpm general small round can line; the 30/50cpm rectangular small can line; 30cpm pail can machine line, and a 30cpm big can lines that are square. Our products are exported not just to the local market, but additionally to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with years of experiences. We offer the latest technology, high-quality can equipment and top after-sales services. You can select Jiujiang Yongxin Can Equipment Co., Ltd to make your cans.

We have a skilled team who can provide after-sales support to Tin can manufacturing process our machines in a proper way.

Our professional sales team are waiting for your consultation.