Thanks to our daily grind, I would be able to make considerable progress in the following innovation. Above all, tin can making machines are worthy of respect as they bring a lot to our everyday life. Canning machines for producing food and drink cansThis next part is given more attention about how tin can making machines are working together. Evolution of tin can making machines with time. Today, those same machines are equipped with the latest technology and efficacy with computer software to verify that operations go off without a hitch. Thus more cans are made in short time at high speed and eradicates errors from the old production line while there used to make hands. Components of Tin Can Making Machines, Investing. As one looks closer at any tin can making machine, they start to realize it is a complex system of interconnected pieces. Then there is a DJ, press, and mold roller that works as an entirety to prepare the tin to be a fully functional can. Moreover, the machines are required to run on electricity. Hands-on systems, like these, revolutionized the making processes. Towards Automated Production Lines,. Unfortunately, the hands-on method to making cans ultimately is a waste of time and energy.

Recording machines Can making machinery Manufacturing of Cans are process based, using metal due to manufacture variations in the body sheet (metal true and proper), & tooling/dies is to be necessity...getBody Sheet Metal: Scenario # 1 - Beverages The majority beverage containers use aluminum for their can manufacturing. Effectively, the jobs have to be related for his or her use in steel cutting ones faster and with extra accuracy being predominant than human counterparts. Further, these machines also save the large machinist storage cost that produces more cans in less time and such pricing will benefit consumers.

The challenging of tin can making machine production lines are obvious for the reason that it contains five stage processing to complete a high-end final product. It starts from the metal sheet feeder having raw materials delivered to cutting & shaping station, then into welding stations onwards quality inspection before dispatching. This is a Die forming operation; all steps are important in the final joining or soldering of liquid-can-liquid pieces, as well due to can prepartion for USD-wide distribution.

How the tin can making machines work internally. From the metal sheet feeder to finishing station, each component has its importance. The machines are mostly created to perform some metal forming, cutting them and weld them at personal levels in other for water packing.

Hence in this aspect we should say that tin cans making machines are the building of human brains equipped with all facilities to clear life and bring these tins at a much faster pace. This simple, of course means that the availability is speed and then ultimately we have coming (without however loose too much detail), in production costs: concentration; all consumer goods available.

Evolution of tin can making machines with time These machines today have the best technology and efficiency With computer programs to control their operations, tin can making machines in use today are able to create more cans at a higher rate of speed than when the process is performed by hand while eradicating errors.

Upon closer inspection, a tin can making machine is an intricate collection of interconnected parts. Among these are rollers, presses and molds which all work in conjunction to form the metal into a functioning can. Furthermore, the machines require electricity to function demonstrating the role of technological advancement in improving processes for production.

Historically, cans have been a labor-intensive process made of hand requiring significant time and storage capabilities. But this method made the production process much faster when automated assembly lines were introduced. These advances require a combination of machine collaboration for producing 1000s or 10,000 cans continuously day in and night out without any tiredness with the result9ing system becoming intelligent fully.

Improving | Increasing Work Flow With The Use Of Tin Can Making Machines

Tin can making machines Tin Can manufacturing has several process, involving mechanical or automated tin can machinery which processes the sheet metal by using a tool (dies) to perform engineering operation. Their use to carry out metal cutting tasks faster and more accurately with shaping works far exceed that of humans. Moreover, these machines help in huge time and cost savier that can manufacture more cans within short period of time which helps to reduce the price for consumers.

The difficult of tin can making machine production lines are apparent when considering the different stages that go into creating a cutting-edge finished product. The process starts at the metal sheet feeder, where raw materials are delivered and moves onto cutting & shaping station followed by welding stations then finishing off with quality inspection before shipping. This is called a die forming operation; each stage serves an essential role in the cuboid to pieces of cans and tin component joining or soldering stages as well as preparation for can global distribution.

Exploring the Complexity of a Tin Can Making Machine Working

The workings of tin can making machines internally. Each component is important from the metal sheet feeder to the finishing station. The machinery is built to orchestrate a set of tasks that include metal flattening, cutting and welding them together at individual standards in order to be packaged.

So, in this regard we can say that tin cans making machines are the creation of human minds which have really made life easier by producing these tins with greater efficiency and ease. These machines simplify and speed up the production process, which leads to a reduction in costs for basic items available to consumers.

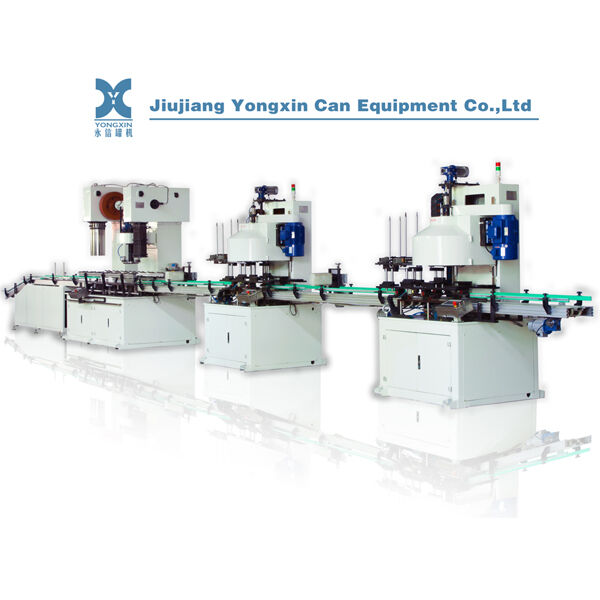

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is tin can making machine production line and manufacture of tin can equipment. Today, we have high-speed main automatic machines such as 40/60cpm small round general line for cans, 30/50cpm small rectangular can line, 30cpm conical can line, 30cpm big square can line. Our products are shipped not just to the local market, but also to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with many years of experience. We provide advanced technology, high-quality can equipment and top after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is your top choice for making cans with our machines.

Jiujiang Yongxin Can Equipment specialized in the production of cans machines, with over 20 years of expertise in the manufacturing industry, Provide all kinds of can making equipment in semi-automatic and tin can making machine production line. The best quality and service. Can sizes range from 0.1L-25L for round and square cans. These cans are used for food, paint and for any other general purpose. Yongxin can making machine is recognized by can makers as reliable and a high-quality can maker. Visit our website to find additional information on the process of making cans.

We have a tin can making machine production line that offers after-sales service to assist customers in maintaining and utilize our machines in a proper way.

We are JIUJIANGYONGXIN Equipment CO., LTD is accredited by CE certification, SGS testing and other certificates, for products of the automatic can seaming machine, and automatic square and round can body-making machines. We also have over 84 patents like for tin can making machine production line, for automatic round and rectangular can seaming machine, for automatic paper can seaming machines and many more, all of which are protected by the independent intellectual property rights. The company was recognized as a high-tech company within the province of JIANGXI Province, China.

Our professional sales team are waiting for your consultation.