How Tin Can Packaging Machines are Helping Better Food and Beverages.ResumeLayoutEnglish

Packaging in the food and beverage industry has led to significant changes, making machines for tin can packaging irreplaceable. They are inevitable for quick and labor saving packaging activity in any packing carried out at a factory We will take it even further in this article by highlighting the five tin can packaging machines that are redefining the industry;

Regarding high-volume, the Bosch VPC 2700 is an innovation in terms of large-series production. The TKW employs an in-line, servo-driven barrel-sleeve labeler capable of applying wraparound labels at speeds up to 600 cans/min making it among the fastest available. With capabilities including automated infeed systems and robotic handling for more advanced requirements, the VPC 2700 ensures a smooth & reliable operation to package various products such as beverages or even fresh fruits, vegetables up to pet food. What they are saying is that, handle the different sizes / types ( of can ) AND at higher volume, yet operation OR user-friendly WITH lower product changeover timings for a Raw to Ready production.

Streamlining production processes is a necessary priority for your food and beverage industry. Scholle IPN's FlexiBag is packaging technology that offers both high performance and unrivaled convenience for branded food products packed from sustainable sources. And it does all of this while minimizing material waste and maximizing protection as well the shelf life in contrast to regular canning methods. The space-saving design makes it easy to stack and transport perfect for a range of applications hot or cold (English)

Tin Can Packing Machine of High Speed and High Precision

Meanwhile innovations in the sector require ever more efficient and precise machines for packaging tablets, blister packing etc., as is the case with Krones' Contiroll HS model. This label machine is equipped with a high speed of 81000 cans per hour which helps in fast labelling and consists features like servo driven labels dispensing. A user-friendly interface and the ability to handle various can sizes/shapes (energy drinks, soda, beer) also makes it neutral in product processing points when switching from one item to another.

Food and beverage producers rely on packaging optimization, the Combi RCF offers a way to meet each of these needs. Material waste is significantly reduced when die-cut boxes are used instead of standard cases on one of these case-packing machines, designed specifically for this application It will feature a touchscreen control panel for intuitive operation, automated infeed systems to minimize downtime and rapid changeover capabilities-in response the latest market trends-and allow it to better handle both irregular can sizes/shapes while maintaining high quality throughput on packout.

Other equipment that helps push the productivity needle for food & beverage processors: Canmatic CL high-speed labeling; F416 seaming and filling from Ferrum, case-packing machine E-Z 215S. These machines do seem to be the ideal choice for improving production line processes as in addition flat screen interfaces are clear and simple to operate enabling a more precise automation of the gauge changing process, whilst at the same time they can also boast about quick changeover times. These are the state-of-the-art tin can packaging machines and will have to enhance loading, capacity and other specifications of these packing operations along with cost reducing in complete production processes for producers.

To sum up, the packing technology in food and beverage sector is provided with all overall improvement to achieve an excellent productivity processes meanwhile tin can filling machine operating as a useful environmentally friendly edge pack tech for this company. This creates an opportunity for manufacturers, who take advantage of it to enhance their productivity and survive in the race where they are able to supply goods on a timely basis, ensuring that lower cost of ownership is passed onto customers.

Jiujiang yongxin can equipment co. Ltd could send a tin can packaging machine to visit our overseas customer's factory to install our Tin Can Making Machine production line. We have a professional team to provide a good after-sales service to assist customers in using our equipment in a way that is suitable and also to keep our machine in good condition regularly. We offer excellent customer service to more than 2000customers around the world. We also export to more than 60 countries.

With over 20 years of experience in can manufacturing, Jiujiang Yongxin Can Equipment tin can packaging machine. We offer all types of can making machines both semi-automatic as well as automatic. They offer the best quality and service. Can sizes are 0.1L-25L for square and round cans, and can be used for food, paint as well as for general purpose. Yongxin can maker is well-known to can makers as a reliable and top-quality can maker. More details on making cans, welcome to visit our website.

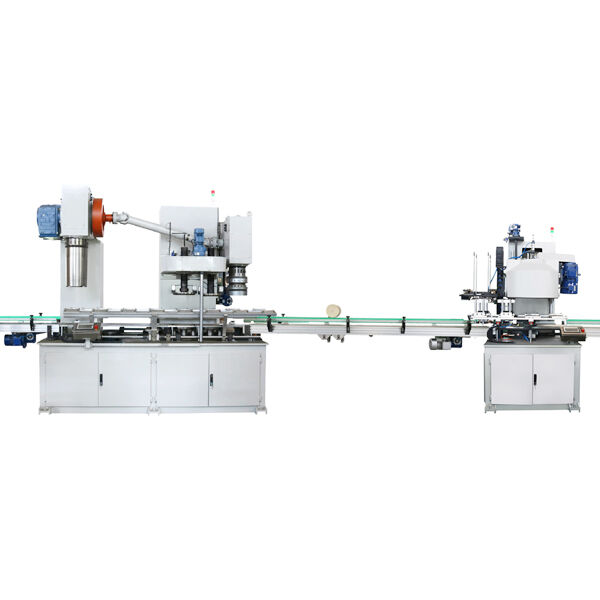

Jiujiang Yongxin Can Equipment Co., Ltd has been dedicated to tin can machines developing and tin can packaging machine since 2005. We have high-speed machines, including the 40/60cpm general small round can line; the 30/50cpm rectangular small can line; 30cpm pail can machine line, and a 30cpm big can lines that are square. Our products are exported not just to the local market, but additionally to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with years of experiences. We offer the latest technology, high-quality can equipment and top after-sales services. You can select Jiujiang Yongxin Can Equipment Co., Ltd to make your cans.

We, JIUJIANGYONGXINCAN CO. LTD is accredited with SGS, tin can packaging machine and other certifications for our automated can seaming machine, and automatic square and round can bodies. Furthermore, we have over 84 patents, like for automatic small rectangular can body-making machines, for an automatic round and rectangular can seaming machine as well as an automated paper can seaming equipment and many more, all of which are secured by independent intellectual rights of property. The company was recognized as a high-tech enterprise in the province of JIANGXI Province, China.

Our professional sales team are waiting for your consultation.