Ever wondered how the tin cans you get your favorite snacks in are manufactured? It is really an interesting process! This technology involves the tin making machine, crucial to this process. It really does creates the can into its usual cylindrical shape and appearance.

Now, to the question on your mind: How much does one of these machines really cost? The subject is not quite simple to response and hangs on a lot of factors which we can explain in the following general guide.

When examining cost of a tin making machine, there are numerous factors that need to be taken into consideration so as o fully understand the quotation. One key consideration is how complicated the machine itself appears to be. More advanced builds have more features and cost a little (or significantly) higher than simpler machines.

Secondly, the capacity of machine is an essential factor which decide what price range this product has. Naturally, you often get what you pay for: a larger machine will usually cost more than smaller one. In addition, price of the machine also influenced by contenticultured materials. Heavy Duty machines are made from quality components and, as such can me more expensive.

Also take into account whether the machine has been used before or not. The cost of regenerative blower is accordingly the immediate expense circuitous with propelling another machine as well as the concealed upkeep and fixes related to a used example that, in actuality can level up bring down by utilization expenses throughout its lifetime.

With the knowledge about what constitutes a cost for tin making machines, it is time to identify where you can find the best bargain. An option is to leave aside the comparison between prices of different manufacturers. If you spend some time researching, you might find a machine that does everything else your looking for at an even lower price point.

Or, you may consider investing in a second-hand machine. Yes, this is a medium-risk option but you can save money on getting more value for your dollar. But be sure to carefully check and try out any used machines before you buy them.

Selecting the best machine can be difficult for those entering into tin can manufacturing or production processes, especially for beginners; There are some basic points to consider such as:

First, determine the size of cans you plan to make and ensure that the machine is capable be selected for your application.

Think about how many cans you plan to make and listen. Select a machine that can keep up with your production needs without having downtime or stoppages.

Keep your budget in mind. Although investing in a good quality machine is necessary, you also do not want to overspend beyond your financial capability.

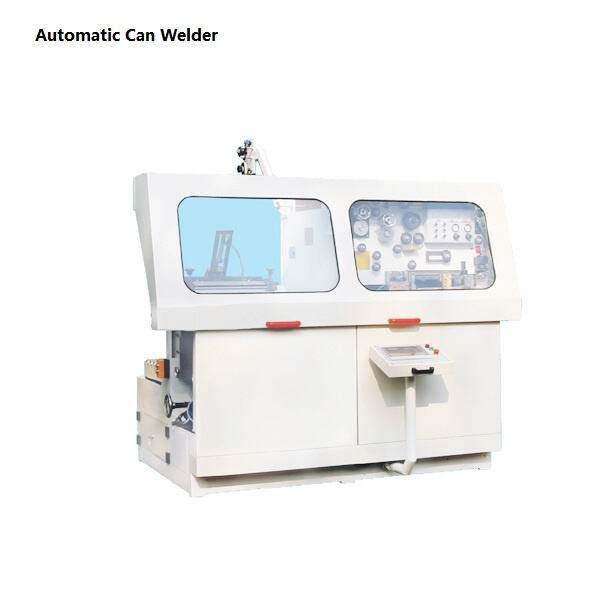

Look for machines with features that make your operations more efficient. For example, some machines may provide an automatic feeding or cutting feature that can save you even more time and effort.

Just before you make up your mind which tin making machine to buy for great can ends production there will be other factors that needs due considerations. First, consider the maintenance and repair costs of operating this machine in order to continue with sufficient affordability.

Also evaluate the manufacturer's training and support. How will learne how to use this machine? If there were bugs, what type of support is available. You need to be confident that everything required to achieve success is available easily.

Finally, think about your business into the future. Are upgrades or additional pieces of equipment predicted in your future? If so, make sure that the device you pick will work with some enhancements you might want to introduce at a later stage.

To summarize, the pricing of tin making machines is dependent on numerous factors. With knowledge of the cost factors and actively finding good deals way you can get a machine that fits your needs as well financial aspirations. But do the research and make your own smart choices after you absolutely know all of this information.

Jiujiang yongxin can equipment co. Ltd could send a tin making machine price to visit our overseas customer's factory to install our Tin Can Making Machine production line. We have a professional team to provide a good after-sales service to assist customers in using our equipment in a way that is suitable and also to keep our machine in good condition regularly. We offer excellent customer service to more than 2000customers around the world. We also export to more than 60 countries.

Jiujiang Yongxin Can Equipment specialized in the field of making cans machines with more than 20 years of experience in the tin making machine price. Provide all kinds of can making machine in semi-automatic and automated versions. With high quality and best service. Can sizes range from 0.1L-25L in square and round cans for paint, food and general use. With excellent after-sales service and reliable running conditions, Yongxin Can making machine has enjoyed the trust of can makers. With years of study in the field, we've come up with an automated UN Pail line. Closed drum making line. Check out our website for more details on making cans.

Jiujiang Yongxin Can Equipment Co., Ltd has been devoted to Tin can equipment development and manufacturing since 2005. We have now tin making machine price like 40/60cpm small round general can line, 30/50cpm smaller rectangular can line, 30cpm conical can line, 30cpm big square can line. Beyond the domestic market our products are exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and many more. As original experienced manufacturer of advanced technology, we provide, top quality can machines as well as a great after-sales support. We at Jiujiang Yongxin can equipment Co., Ltd is your top choice when it comes to can making machines.

We are JIUJIANGYONGXIN EQUIPMENT CO., LTD, is accredited through CE certification, SGS testing and other certificates, for tin making machine price, automated round and square can body-making machines. We also hold Patents 84 for various products like automatic small rectangular can bodies, automatic round and rectangle can seaming machines, automatic paper can seaming equipment and other. These are protected under independent intellectual property rights. It was recognized as a "high technological enterprise within the Province of JIANGXI Province" in China.

Our professional sales team are waiting for your consultation.