The former will lead to the legend of stannous, which once upon a time had tough and rusty resistance (as well as) This brings us to today and how tin remains a favoured material in modern manufacturing processes.

Tinsmiths are those people that have optimize in carrying out the work with tin. Tin smiths also use a variety of tools including hammers, and shaping tools to mold the tin into different forms. These are specified things- from dressing as little dolls to solid tin cans, hardware bit of other stuff like cars and planes. adeptly skilled tinsmiths can efficiently form these in anyway that they wish.

New technologies have helped this area of production, although traditional craftsmanship still plays a significant role in tin making. Today, companies use computer programs to plan everything and design the tin product down to the last detail before starting to make things a reality. In addition, the introduction of robotic assistance has automated repetitive duties improving productions efficiency.

The process of making tin is an intricate one that requires years of practice to produce high-quality products. First, the tin is melted and poured into a mold to give the base figure of whatever item you are looking for. Tin is then worked on by tinsmiths using special tools and machinery to refine the tin,and perfect it for a flawless finish.

Side note: is nothing wrong with trying to achieve a better environment, but it should always put somewhere in the the top priority of your guide team efforts if not number one.

Balance in Sustainable Tin Manufacturing The most notable is tin, one of the greenest metals available only time and time again without compromising on its strength or quality. Recycled tin is generally used by a lot of manufacturers to cut down waste and requisition for raw materials. But taking proper steps to not harm the ecosystem - as in utilizing energy-saving equipment - shows that the industry is concerned with being environmentally responsible.

The tradition of tin making stretches back hundreds of years, and as time has gone by we have combined centuries-old skills with the best in modern technology to create new advances. In the 21st century, these tinsmiths follow a perfect blend of time-honored practices mixed in with modern-day advancements to create both handcrafted and innovation solid tin items that intrigue consumers.

At the heart, Tin Manufacture is a wonderful art that shine by skill so on experience and tender of depict Today tinsmiths continue to fabricate beautiful and useful tin goods by blending old-world artisanship with modern technology. Whether looking for a timeless colonial memento or reliable packaging, tin has this special something that marries the old and new effortlessly.

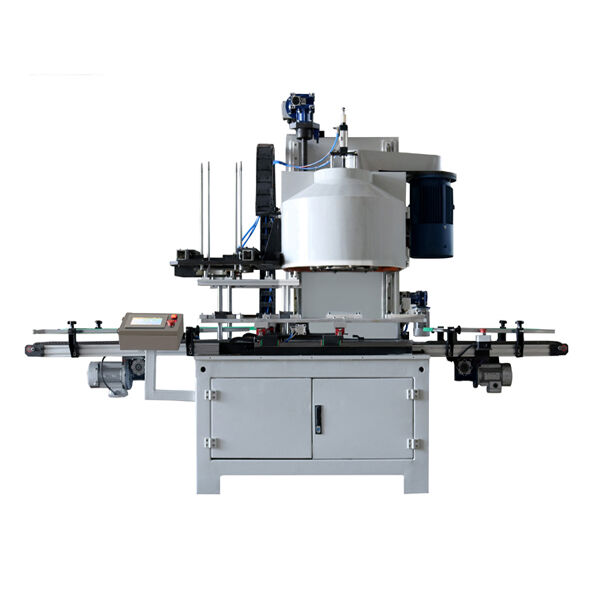

Jiujiang Yongxin Can Equipment Co., Ltd has been devoted to Tin can equipment development and manufacturing since 2005. We have now tin manufacturing like 40/60cpm small round general can line, 30/50cpm smaller rectangular can line, 30cpm conical can line, 30cpm big square can line. Beyond the domestic market our products are exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and many more. As original experienced manufacturer of advanced technology, we provide, top quality can machines as well as a great after-sales support. We at Jiujiang Yongxin can equipment Co., Ltd is your top choice when it comes to can making machines.

With over 20 years of experience in the field of can manufacturing, Jiujiang Yongxin Can Equipment specializes in the production of cans using machines. We offer all kinds of can-making equipment, semi-automatic and automatic. The best quality and service. Can tin manufacturing for square and round cans, and can be employed in the fields of food, paint and for any other general purpose. Yongxin can making machine is known to can makers for being an efficient and reliable can maker. Visit our website to find additional information on the process of making cans.

We are JIUJIANGYONGXIN Equipment CO., LTD is accredited by CE certification, SGS testing and other certificates, for products of the automatic can seaming machine, and automatic square and round can body-making machines. We also have over 84 patents like for tin manufacturing, for automatic round and rectangular can seaming machine, for automatic paper can seaming machines and many more, all of which are protected by the independent intellectual property rights. The company was recognized as a high-tech company within the province of JIANGXI Province, China.

We have a skilled team that can offer after-sales services to tin manufacturing and use their machines properly.

Our professional sales team are waiting for your consultation.