Чи задумувалися ви коли-небудь про захопливий процес, який доставляє ваші улюблені напої та їжу від точки А до тих стильових металевих банок? Все повертається до чудового прес-машини для банок з кинцем. Цей сучасний інструмент було створено для перетворення аркуша (цинку) на революційні металеві контейнери, які зберігають їжу для зберігання та перевезення в магазинах. Подорожуйте разом з нами цим цікавим світом прес-машин для банок і дізнайтеся, як ці інструменти знову революціонують сучасну виробничу галузь.

Машини для пресування консервних банок значно вдосконалились з моменту їх появи. Компанія колись виготовляла їх вручну, використовуючи ручні крани, і такі машини вимагали багато часу для створення однієї блоку або цеглини. Сьогодні вони оснащені електричним мотором і повністю автоматизовані завдяки технологіям. Це дозволяє створювати широкий асортимент форм і розмірів консервних банок завдяки впровадженню технологій (комп'ютерних систем). Технологія та продукція машин для пресування консервних банок досягли такого рівня, що підприємства можуть задовольняти запити навіть при їхньому щоденному зростанні.

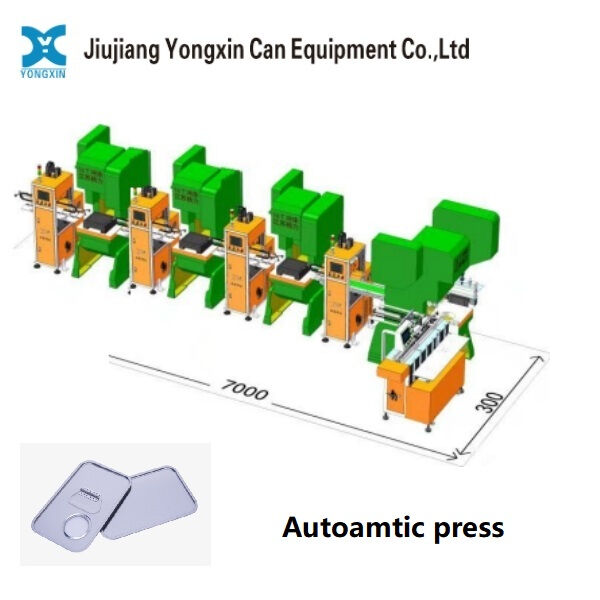

Де Автоматичний Закупажувач Консервних Банок, який працює за допомогою місцевого Пресу Машини та надається Металевими Консервними Банками!

Що відбувається у механізмі машин для пресування консервних банок. Механічні та рухомі частини у машинах для пресування консервних банок дуже точні, всі вони працюють гладко, поки металеві листи набувають форми ємностей. У прикладі підходящий рухомий металевий прут закриває кожен лист і рухається за допомогою ролерового механізму, який створює необхідну форму. Ця конусна склеювальна машина допомагала забезпечити підтримку ролерів для металевих листів та різальних інструментів у точній формі. Як наслідок, різні машини для пресування консервних банок використовують ці деталі та вставляють їх у зазор, що допомагає у створенні таких міцних та гнучких банок.

Підприємства, які вибирають використовувати такі машини для пресування консервних банок з жести, мають багато переваг. Ці машини виробляють велику кількість продукції і випускають тисячі банок кожного дня, щоб задовольнити ринковий запит. Лінії також забезпечують однакову товщину і розміри банок, що гарантує високу якість. Крім того, вони економічні не тільки завдяки збереженню праці, але й через меншу кількість відходів, що призводить до більш значних збережень витрат на виробництво.

Щоб максималізувати промислову продуктивність, потрібно зменшувати використання матеріалів на одиницю виробництва. Цей погляд був проілюстрований у машин American Tin Can Press на виробничому конвеєрі. Машина працює без постійного нагляду, виробляючи систему виробництва рідини з дуже високою продуктивністю, яку неможливо досягти ручним трудом. Отже, вони можуть працювати 24/7 без жодної паузи у виробництві, що робить підприємства більш ефективними чи прибутковими.

Це, в свою чергу, призводить до значних екологічних та економічних переваг для прес-машин з жестяних банок. Вони зменшують відходи після виробництва, роблячи деякі банки з більшою висотою, але з тією самою товщиною для всіх розмірів банок. Жестяні банки, як правило, можуть бути перероблені і також є екологічно безпечними. Застосовуючи таку технологію, підприємства, які інвестують у їх використання, отримують можливість досягти довгострокових економічних переваг через зниження витрат на виробництво та покращення продуктивності, що призводить до значних заощаджень, які можуть перетворитися на більшу маржу (прибуток).

Іншими словами, машини для пресування консервних банок є основою сучасної промисловості; особливо упаковки продуктів харчування та напоїв. Проте це не відповідає технологіям, які забезпечують критичних друзів, які допомагають продуктивності зберігати лінію та знижувати витрати, щоб ми могли навантажуватися пакетами радості (або банками коли) від пресу до вихідного закруту - при чому наші бізнеси зараз гуртуються "" навколо """технологій, навіть самі до них належать. Компанія виготовляє надзвичайно ефективні машини, які також сприяють чистішому середовищу та перевизначають рентабельність вкладень для підприємств, яким потрібен цей цикл в центрі того, що вони роблять.

З 2005 року компанія Jiujiang Yongxin Can Equipment Co., Ltd присвячена дослідженню та розробці обладнання для консервних банок. У нас є високшвидкісні автоматичні машини, такі як прес-машина для консервних банок; лінія квадратних малих банок 30/50 циклів на хвилину; лінія машин для ведёр з 30 циклами на хвилину, а також квадратна лінія великих банок з 30 циклами на хвилину. Крім внутрішнього ринку, наша продукція також експортується до Індії, В'єтнаму, Індонезії, Тайланду, Дубая, Йорданії, Саудівської Аравії, Греції, Кенії, Південної Африки та інших країн. Ми є передовим виробником з багатою досвідчиною. Ми пропонуємо найновішу технологію, високоякісні машини для банок, а також відмінне післепродажне обслуговування. Компанія Jiujiang Yongxin Can Equipment Co., Ltd стане вашим найкращим вибором для машин по виготовленню банок.

Ми, КОМПАНІЯ JIUJIANGYONGXIN CAN EQUIPMENT CO., LTD, маємо акредитацію CE сертифікації, а також сертифікацію для наших продуктів, таких як автоматична машини для склеювання консервних банок, автоматичні машини для виготовлення круглих та квадратних корпусів консервних банок. Також ми маємо 84 патенти для різних продуктів, наприклад, автоматичні малі прямокутні корпуси консервних банок, автоматична кругла і прямокутна машини для склеювання консервних банок, автоматична машина для склеювання паперових банок тощо. Вони захищені незалежними правами інтелектуальної власності. Компанія була визнана високотехнологічною фірмою у провінції Цзянсі, Китай.

При виробництві консервних банок за допомогою прес-машини, компанія Jiujiang Yongxin Can Equipment спеціалізується на виготовленні банок з використанням машин. Ми пропонуємо всі види машин для виготовлення банок, як напівавтоматичні, так і автоматизовані, з найвищою якістю та обслуговуванням. Розміри банок — від 0,1 л до 25 л для квадратних та круглих банок. Ці банки використовуються у рослинному малюнку, їжі та загальному призначення. Виробництво банок від Yongxin визнається виробниками банок як надійний та високоякісний виробник. Подивіться наш сайт, щоб дізнатися більше про виробництво банок.

У нас є вправна команда, яка може надавати послуги після продажу для прес-машини консервних банок та правильно їх використовувати.

Наша професійна команда з продажу чекає на вашу консультацію.