Металеві консервні банки використовуються для збереження багатьох речей; металеві банки з їжею або предметами, такими як овочі та фрукти, солодощі, корм для гральних птахів, домашні фарби, косметика, різні види кремів, шампуні, колір волосся, автотовари, масла, побутова хімія, така як чистячі засоби для дому, деграсер, засоби проти жиру, моючі засоби, освіжувачі повітря, парфум. Металеві банки можна знайти у будь-якому добром супермаркеті та магазині продуктів; вони продаються як гарячі пиріжки. Щоб створити металеву банку, потрібно пройти послідовність процесів. Це відео про те, як виготовляються металеві банки, і воно поетапно пояснює процес, щоб ви бачили, як листи заліза перетворюються на банки.

Виготовлення банки починається з листового металу. Отож, як виготовити банку? Залізо також достатньо міцне, щоб захищати будь-які вміст банок. Рулон металу вирізається у круглі частини компанією YONGXIN t виробничий апарат для виготовлення консервних банок які варіюються за ширини та товщини, що відповідають для виготовлення консервних банок. Після роздроблення ці частинки отримують покриття яскравим оловом. Листова сталі отримує застосування блискучого олова; ця оболонка захищає жалезо від ржавчини при взаємодії з вологістю та киснем.

Потім вам потрібно виготовити верхню та нижню частини вашої банки. Ці краї отримуються шляхом пресування металу таким чином, що коли ця машина утворює його з обох боків, кожна сторона матиме один край для закріплення ручок у кутах. Вставляючи іншу кришку всередину, ви гарантуєте, що вони будуть дуже туго сидіти наверху, а потім вона проходить герметизацію, де залишається, поки хтось не захоче, щоб їжа всередині не була забрудженою, і нічого не протікало.

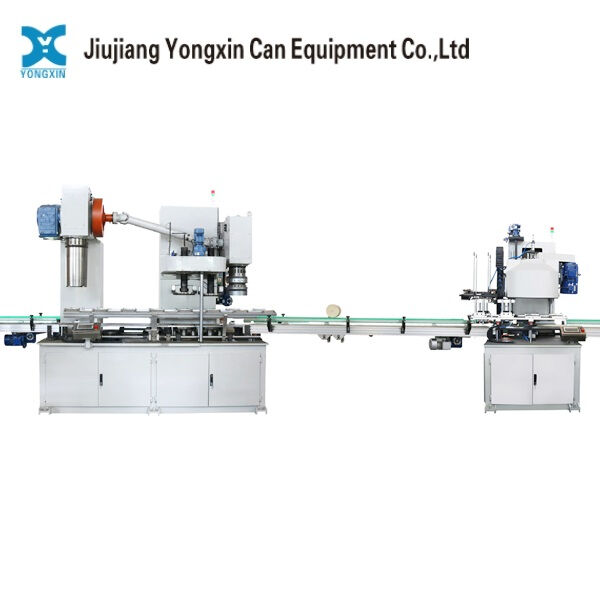

Різні машини причетні до виготовлення консервних банок, кожна з яких виконує певну роль у процесі виробництва. Машина для розкрію, яка розрізає метали на великі розміри, одна з них. Наприклад, враховуючи важливість форми, формуюча машина робить метал так, що після обробки він повинен бути 'Can wagtail'. YONGXIN машина для запечатування консервних банок також відноситься до цієї категорії, оскільки вона надійно тримає кришку на банці; і є деякі машини для закріплення кришки, які забезпечують її прекрасне пригнання.

При виготовленні жестянки важливо для контролю якості вилучити всі дефекти, які можуть бути небезпечними для кінцевого користувача. Як працівники, так і обладнання від YONGXIN апарат для консерв перевіряють контейнери на різних етапах процесу, щоб забезпечити їх безпеку. Так само, як і випуклість або тріщина, існує спеціальне обладнання для перевірки цих банок на недоліки, які можуть впливати на загальну якість контейнера. Отже, тільки банки високої якості потрапляють на ринок для продажу. Дефектні і неправомірні банки вилучаються з виробничих ліній, щоб захищати споживачів та їх інтереси.

Банки з жалеза є чудовим прикладом екологічної дружністі. Багато металу, що виробляється сьогодні, отримують шляхом переробки, що свідчить про його походження з використаних банок та інших видів металів, таким чином економлячи природні ресурси та запобігаючи забрудненню. Деякі підприємства використовують відновлювані джерела енергії, такі як сонячна або вітрова енергія, щоб зменшити загальну кількість споживаної енергії під час виробничого процесу. Забезпечення присутності яєць на нашому столі підтримує спосіб життя людини у цьому світі, тому забезпечення тривалої природи можливе протягом багатьох поколінь.

По суті, міцні люди вибирають металеві консервні банки, оскільки вони довговічні. Багато споживачів переважають металеві банки над іншими, тому що їх можна складувати, що сприяє економії місця у шафах та кухнях. Крім того, вони дуже дешеві, і вам потрібна банка для зберігання їжі багато років до її вживання, оскільки їжа не може портитися у збереженому стані. Ці банки допомагають упаковувати їжу так, щоб вона залишалася свіжою, запобігаючи її портлявості. Також, у порівнянні з іншими матеріалами для упаковки, такими як пластик або тетра паки, металеві банки зазвичай коштують менше, що означає, навіть ті, хто хочуть якості, але все ж таки хочуть зекономити гроші, знайдуть їх добре цінованими.

Компанія Jiujiang yongxin can equipment co. Ltd може відправити лінію виробництва консервних банок для відвідування заводу нашого зарубіжного клієнта, щоб встановити нашу лінію виробництва консервних банок. У нас є професійна команда, яка забезпечує хорошу післяпродажну службу для допомоги клієнтам у використанні нашого обладнання у відповідний спосіб та регулярно підтримує нашу машину у добром стані. Ми надаємо відмінне обслуговування більше 2000 клієнтів у всьому світі. Ми також експортуємо у більше 60 країн.

Компанія Jiujiang Yongxin Can Equipment Co., Ltd з 2005 року присвячена розробці та виробництву обладнання для консервних банок. Зараз ми маємо лінії виробництва консервних банок, такі як лінія маленьких круглих загальних банок 40/60cpm, лінія менших прямокутних банок 30/50cpm, лінія конусних банок 30cpm, лінія великих квадратних банок 30cpm. Крім внутрішнього ринку, наша продукція експортується до Індії, В'єтнаму, Індонезії, Тайланду, Дубаю, Йорданії, Саудівської Аравії, Греції, Кенії, Південної Африки та багатьох інших країн. Як оригінальний досвідчений виробник сучасних технологій, ми надаємо машини для консервних банок найвищого якості, а також чудову післяпродажну підтримку. Компанія Jiujiang Yongxin Can Equipment Co., Ltd є вашим найкращим вибором, коли йдеться про машини для виготовлення консервних банок.

Лінія виробництва консервних банок Jiujiang Yongxin Can Equipment має більше 20 років досвіду у галузі виготовлення консервних банок. Представляє різноманітні машини для виготовлення банок у напівавтоматичних та автоматизованих версіях. Висока якість та найкращий сервіс. Розміри банок варіюються від 0,1 л до 25 л у круглих та квадратних формах для їжі, фарби та загального використання. З надійними умовами експлуатації та хорошим післяпродажним обслуговуванням, машини для виготовлення банок Yongxin заслужили добру репутацію серед виробників банок. Після багатьох років досліджень ми розробили автоматичну лінію UN Pail. Лінія виробництва закритих баків. Відвідайте наш сайт для отримання детальнішої інформації про виготовлення банок.

Компанія JIUJIANGYONGXINCAN CO. LTD має акредитацію SGS, CE та інші сертифікації для нашого виробничого конвеєра жестянки, а також для наших автоматичних круглих та квадратних корпусів жестянок. Також у нас є більше 84 патентів, включаючи автоматизовані малі прямокутні корпуси жестянок, автоматичні круглі та прямокутні машини для склеювання жестянок, а також автоматична паперова машина для склеювання жестянок та інші, які захищені незалежними правами інтелектуальної власності. Вона була визнана технологічно передовим підприємством у провінції Цзянсі, Китай.

Наша професійна команда з продажу чекає на вашу консультацію.