Hi there! What is can making machinery? It is a very interesting machine that produces cans and we see most things in store for the can. So in today text, we are going to know about can manufacturing machines their main functions and workings.

A can manufacturing machine is an amazing and gigantic machines that manufacture the cans which we savor in installing our favorite foods or beverages. They work in industry, producing vast amounts of cans very rapidly. This is so important as it means we have to give enough cans for all the food and drink that us humans love. And these machines would make it impossible for us to have the cans required for everything we own.

One ice cream maker can go to many different screws working in concert. A metal roll, cutter and seamer are amongst the major parts. Material: The metal roll gives birth to the can. This roll is fed through the machine, where it then turns into cans. The cutter cuts the metal to form each can in the right size and shape. Lastly, a seamer is used to clamp down on the can creating an air-tight seal that prevents leaks. For the machine to function in correctly making cans all these parts have got working perfectly together.

High-Speed and High-Precision Form Can manufacturing machines are designed to work at a very fast pace with high accuracy. These machines are often computer software operated. This software sees to it that dictates how fast and efficient your machine works. It provides instructions to the machine on when it should cut metal and enclose our product in a canned environment. It is using this technology that the machine can create a lot of cans in so little time, it really leaves me amazed!

Can making machines can produce cans way quicker and with better precision than people ever could, which is one of its critical advantages. That way they would be able to produce a lot more cans... much faster. This allows the factory to save money and time. In addition these machines are configured to guarantee each can is properly capped. This is very important as this would minimize the risk of seepage, or even contamination which can be really detrimental to those taken in.

The food and drink sector is growing all the time-and not just with new, groovy indie franchises or high street names being set up in a trendy reclaimed barnitude garage place but also growth rates that drive demand for cans higher. The remarkable thing is how quickly can manufacturing machines be engineered to meet these demands. If the factories needs to make more cans, they can add some machines and upgrade them. This flexibility becomes indispensable in those moments when the demand for canned products skyrocket. Since they are such durable machines, you can use these features for many year after years so you may not want to get new one any time soon.

We have a skilled team that can offer after-sales services to can manufacturing machine and use their machines properly.

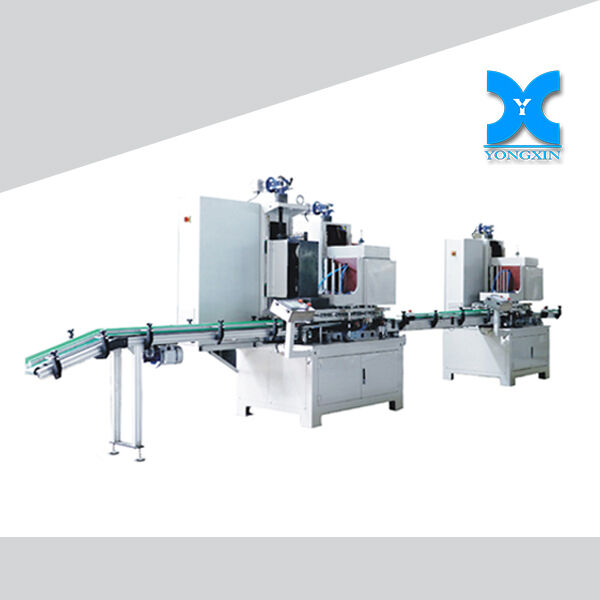

Jiujiang Yongxin Can Equipment specialized in the field of can making machines that have more than 20 years of expertise in the manufacturing industry. We can manufacturing machine semi-automatic and automated versions. High-quality and top service. Can sizes range from 0.1L-25L in square and round cans that are suitable for food, paint and general use. With an excellent after-sales service and stable runing condition, Yongxin can making machine has earned a favorable reputation among can makers. With many years of research, we have developed the automatic UN Pail line. Closed drum making line. Check out our website for more details on making cans.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is can manufacturing machine, CE and other certifications for our can seaming machines, as well as for our automatic round and square can bodies. We also hold Patents 84 for various products like small, automatic can bodies that are automatic round and rectangle can seaming machinery, automatic paper can seaming equipment and other. They are protected by independently owned intellectual property rights. The company was categorized as a "high technological enterprise in the province of JIANGXI Province" in China.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is can manufacturing machine and manufacturing of Tin Can Machinery. We have high-speed automatic machines, such as the 40/60cpm general small circular can line; 30/50cpm rectangle small can line; 30cpm pail can machine line, and a 30cpm square big can line. Our products are not only exported only to the domestic market but as well to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. As a pioneer manufacturer, we supply advanced technology high-end can machinery and excellent after-sales services. Choose Jiujiang Yongxin Can Equipment Co., Ltd for your can-making machines.

Our professional sales team are waiting for your consultation.