Do you want to create the tin can production for your business? You maybe thinking of improving your old tin can making machine. Either way, you need to carefully compare the prices between different tin can making machines so that you end up with something within your budget and production needs.

When it comes to exploring the universe of tin can making machines and their expenses, there are a few fundamental things that could unequivocally affect its rates. Some Key Points To Keep In Mind :

There are a wide variety of tin can making machines available in various sizes and production capacity. Obviously, bigger machines offering more capacity are going to cost you a lot of cash but if your business relies on their operation then it is money well spent.

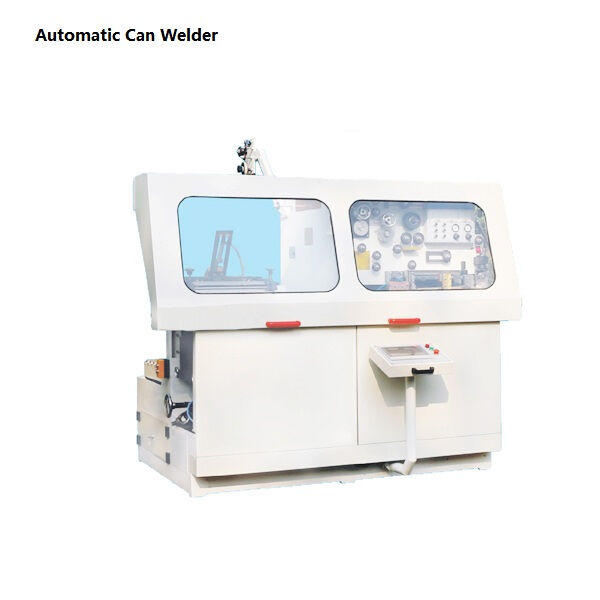

Level of automation: The level at which the machine is automated significantly affects its price. Machines that are 100% automated (e.g. those with robotic handling systems) and require only infrequent human interaction, will generally be more expensive than semi-automated or manual machines.

Materials and Design: The quality of the materials used in building a tin can making machine increases as you go up; some design features might hike its price. For example, equipment with more advanced features such as automatic tool change capabilities of double seam detection will come at a higher price.

Ask About Their Brand Reputation: The brand reputation is also important when it comes to the cost of a can making machine for sale. Brands which are well established for so long may ask a premium from their product.

After you have considered the different elements that can impact on prices for tin can making machines, it is time to come up with a plan of boysenberrying this investment forth into your production line budget. So here are best tips to help you in this planning process.

Market Search: Do market search for the prices you can get a tin making machine before buying and gain knowledge of its prevailing price. If you know how much it costs then, this research will help you have a reasonable budget.

Feature Selection- Determine what features are critical for your production line and which ones your can do without when selecting a machine that meets those requirements but are within budget.

Return of Investment Analysis: The ROI concept should be applied to evaluate if the tin can making machine is beneficial for your business. Then, match the cost of that machine with how much you will save annually on manufacturing from being more efficient.

Also, not every small scale manufacturer will need to invest in a big and expensive tin can making machine. The Bottom Line The kind of insulation you choose may cost a little up front, but there are more affordable alternatives that can meet your production needs without breaking the bank. You might consider:

Manual Tin Can Making Machines - These machines provide a less expensive way to make tin cans, but they need more people and hands. Small-scale manufacturing are well-suited for them.

Semi-Automatic Tin Can Making Machines: A somewhat larger upfront investment is required for a semi-automatic machine, however these machines will have additional automation and inventory capacity spring than their blueprint advice.

Used Tin Can Making Machines - Check Whether A Second Hand TCM Machine Is Right For You Even if it's an older model with cosmetic wear and tear, you are still gonna get good output while saving money.

While a tin can making machine on the premium end of the price scale may come across as an expensive asset upfront, it certainly worth every penny in the long run. So todays we show you some Mandatory reason for increase price points machine.

Improved Operational Efficiency: High-quality machines normally come with upgraded features to increase your production line efficiency. This will allow for increased production capacity and save on manufacturing costs.

Greater Durability and Reliability: Quality machines are typically more well-engineered, so they suffer less downtime as well... which saves a lot of money down the road on maintenance.

Technological Advancements - That new machines often come with technology that may improve the quality and consistency of your green tin can manufacture.

Insumparable, make sure that you pay a full-featured comparison of tin can making machine prices in order to find the most suitable tincan sealing equipment for your production demand and budget. Take account of the different price impacting factors, make concrete plans and look for budget-friendly ways to step into small production scale. Don't forget, a more expensive machine might save you money in the long run due to less maintenance/repairs and better technology.

Jiujiang Yongxin Can Equipment specialized in the production of cans machines, with over 20 years of expertise in the manufacturing industry, Provide all kinds of can making equipment in semi-automatic and tin can making machine price. The best quality and service. Can sizes range from 0.1L-25L for round and square cans. These cans are used for food, paint and for any other general purpose. Yongxin can making machine is recognized by can makers as reliable and a high-quality can maker. Visit our website to find additional information on the process of making cans.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd has been tin can making machine price and production of tin can equipment. We have high-speed automated equipment, like the general small round 40/60cpm can line; 30/50cpm rectangle small can line; 30cpm pail can machine line and 30cpm square big can line. Our products are shipped not just to the local market, but additionally to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with a wealth of experience. We offer cutting-edge technology, high-quality can machines as well as excellent after-sales service. We, Jiujiang Yongxin can equipment Co., Ltd will be your best choice for making cans with our machines.

We are JIUJIANGYONGXIN CAN EQUIPMENT CO., LTD and is tin can making machine price, SGS testing and other certifications, for the products of the automatic can seaming machine, automatic round and square can body making machines. We also have the benefit of 84 patents on products like automatic small rectangular can bodies that are automatic round and rectangle can seaming machines, automated machine for seaming paper cans and more. They are protected by independently owned intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

We have a tin can making machine price that offers after-sales service to assist customers in maintaining and utilize our machines in a proper way.

Our professional sales team are waiting for your consultation.