Metal tins are common ways to store different kinds of food in the food industry. Such a process, also includes another essential equipment required for keeping these cans air tight & stable is Tin Can Seaming Machine. It is important to food safety as it keeps harmful contaminants like bacteria and air from entering the cans which would cause the spoiled. And that tin can seaming machine is not only safeguarding its consumers from illnesses but preserving food freshness for extended times thanks to the airtight seal.

Modern tin can seaming machines are intelligently designed for the precision maintenance-free food industry. They seal cans fast and at the same time, increasing a lot of ease in production. This makes them ideal for handling various size cans, and they can be custom adjusted according to the needs of different canned foods. Which help improve the efficiency of food packaging operations in general.

With the advancement of technology, tin can seaming machines have evolved steadily over time and now posses quite some capabilities. Machines like this could perform automation, a capability of many contemporary machines which enables them to multi-task just as a human works. They are also designed to be energy-efficient, which in turn saves operational costs and reduces waste. They are also more robust and hence require less maintenance, which makes them long-lasting as well. Technological advancements have indeed revolutionized food packaging and are making it safer for everyone.

A top-quality can seaming machine is a potentially lucrative purchase for businesses in the food and beverage sector. This a machine that helps in maximizing the production line, which makes it less wasteful and more productive. Furthermore, a seamer of higher quality helps to reduce the issues that may arise with food packaging and thus ensures consumer safety. It all depends on businesses the machine they select for their business to match up with operations and advantage provided by it, choose a reliable sturdy as well means lucrative product.

There is an intricate process of can seaming machine work which involves a piece of machinery called the seamer, The latter seals the cans safely by punching or crimping lid into it rendering air-tightness. Designed for precision and speed, these machines offer settings that can be adjusted depending on the size of cans or food items being sealed. Simply adjusting setting has proven to be enough to successfully fulfill a variety of packaging needs simultaneously.

Ultimately, the can seaming machines have a critical role in providing food safety and removing any contamination within the respective industry. Modern machines are extremely efficient and precise, a result of years in technological advancement making them an indispensable asset for any business. If you want to improve your operational results, increase efficiency further reduce waste and make profit investments on a seaming machine of high quality. How these machines work and function are crucial for people who are in the food industry to be able to keep their quality at a high level as well ensure consumer safety.

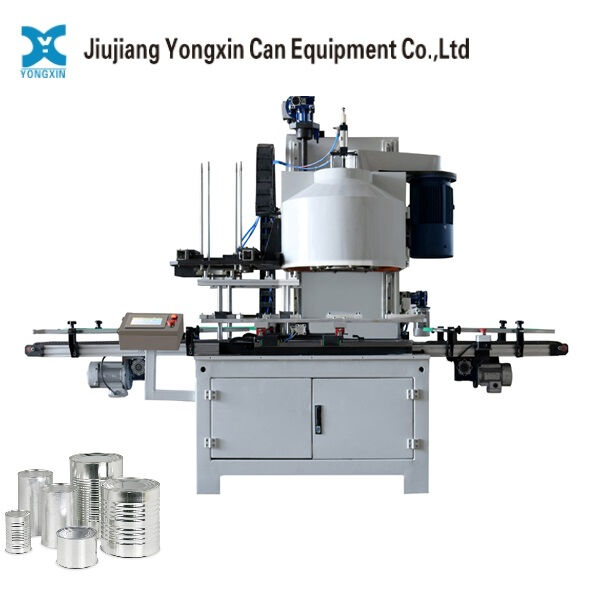

Jiujiang Yongxin Can Equipment tin can seaming machine that have more than 20 years of experience in the can manufacturing industry. Provide all kinds of can making machines in semi-automatic and automated versions. High-quality and top service. Can sizes vary from 0.1L-25L in round and square cans for food, paint and general use. With good after sales service and reliable running conditions, Yongxin Can making machine has enjoyed a favorable reputation among can makers. With years of study we've developed the automatic UN Pail line. Closed drum making line. Visit our website for more details on making cans.

We have a tin can seaming machine that offers after-sales service to assist customers in maintaining and operate our equipment in the correct way.

We are JIUJIANGYONGXIN CAN EQUIPMENT CO., LTD is accredited by CE certification, tin can seaming machine and other certifications for our products of an automatic can seaming machine, automatic round and square can body making machines. We also hold Patents 84 for various products such as automatic small rectangular can bodies that are automatic round and rectangle can seaming machinery, automatic machine for seaming paper cans and other. They are protected by independent intellectual property rights. It was recognized as a high-tech business within the province of JIANGXI Province, China.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is tin can seaming machine and manufacturing of Tin Can Machinery. We have high-speed automatic machines, such as the 40/60cpm general small circular can line; 30/50cpm rectangle small can line; 30cpm pail can machine line, and a 30cpm square big can line. Our products are not only exported only to the domestic market but as well to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. As a pioneer manufacturer, we supply advanced technology high-end can machinery and excellent after-sales services. Choose Jiujiang Yongxin Can Equipment Co., Ltd for your can-making machines.

Our professional sales team are waiting for your consultation.