Seaming: two pieces of fabric are joined together and you may perhaps have seen it being done if ever look into garment plants, seaming machine is obviously a must to have equipment during the making of apparels. This blog read uncovers the fascinating world of seaming machines and how do they function!

During the processing of seaming machines are realized in such a way that kneed and bobbin perform together to stitch two separate pieces of materials into an assembly. The needle goes up, the bobbin is pulled around to grab your fabric on bottom and makes a loop for that sharp top end of the needle. Then, the needle pulls the loop through layers of fabric to create a knot that holds both pieces firmly in place. It is almost hypnotic and the stitches look so pretty! The machines are so versatile, using a variety of stitches to produce the perfect finish.

Overlock Sewing Machine: Over Lock sewing machine used in making over edge stitch to warn the edges of pieces of cloth. A whole lot like the superheros of sewing fabric edges together to avoid fraying.

Flatlock Machine: Meet the flat lock machine that is a proficient design for developing even stitches, therefore making it appropriate for hems as well as also begins base stitch concerned beautiful trimmings just like some sports wear. Fancy look and durable seams.

Blind Stitch Machine The blind stitch machine deals with cloth like a smooth criminal, sewing nearly invisible stitches. It feels like when someone first learns to do thread tricks.

No one knows how to use a chain stitch machine A chain stitching equipment can do robust but also capable of stretchy stitches in the way that is good for decorating. The detailing of feathers on your materials is almost like the mother of seaming world...

Finally, the feed-off-the-arm machine is used for cylindrical and tubular items (originally: sewing jeans). He is the arhchitect of seam, making different.

Seaming machines are really boon as they taking away navigation of time & energy too, but also providing traversal to productivity facet hand by hand. Therefore, that translates into these machines being able to make the most of electricity and automation by sewing fabrics in a high (and precise) speed which enables great help for speeding up production timelines. It is appreciated even more than ever when you have larger garment factories or production lines as every single second counts and time[eff]is the essence here. Secondly, seaming machines contribute to waste management as they use even stitches while sewing with the goal of reducing fabric wastages.

Choose Correct Seaming Machine For Your Commercial Operations

But only purchasing is not enough there are many things you need to ponder while selecting a seaming machine for your own commercial purpose. First step, consider the stitch patterns required by your knits. Now each one of this earth has its own uniqueness when it comes to sewing over anything simpler or even intricate. You should also determine how many rolls of fabric you are going to bulk and from there what your production quantity is. The speed and efficiency differ from one machine to another, so you need your desired effect boosted by more rapid recovery time in business needs, but slow smooth. Should it be taken into account when finally, the budget is concerned with the decision as there are available in all the price range and according to one can match them so this makes a more attractive deal to purchase.

Seaming machines are one of the most necessary tools for being essential in maximizing output while maintaining adequate levels of efficiency and quality simultaneously production system of textiles & garments. These are those machines which help to not only improve operations and eliminate waste but also allow the quality a right building - so as it appears quite worthy enough to get covered over what role they play, since they are obviously playing an important part in taking things towards consistent throughput. The choice of seaming machine follows a delicate give and take in terms of stitch patterns, fabric thicknesses, production rates as well as financial constraints. In the manufacturing world, a machine that works flawlessly will improve production capabilities and goods.

We have a skilled team who can provide after-sales support to seaming machines our machines in a proper way.

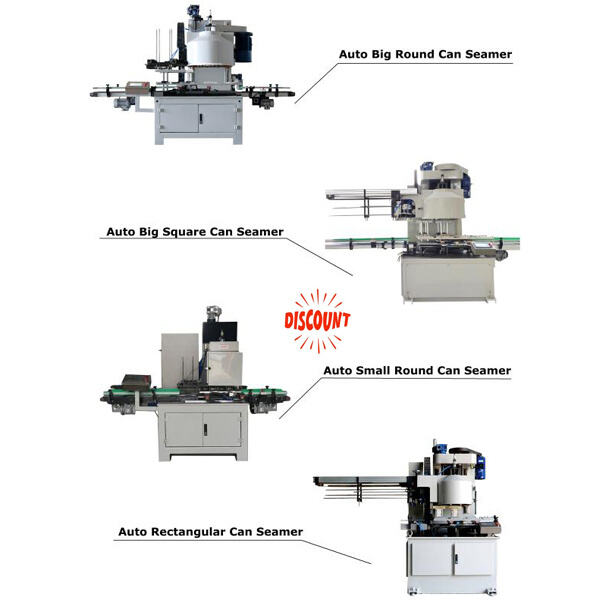

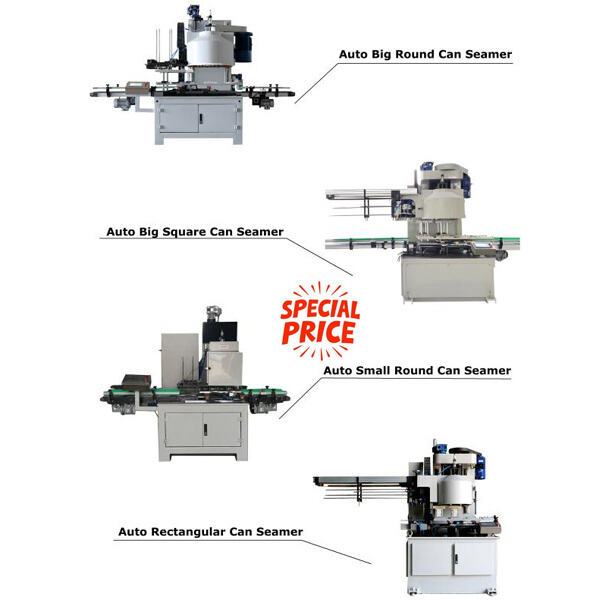

With more than 20 years experience in can manufacturing, Jiujiang Yongxin Can Equipment specializes in can-making machines. We seaming machines, semi-automatic as well as automatic. It is of high-end quality and provides the best service. Can sizes vary from 0.1L-25L in square and round cans that are suitable for food, paint and general use. With an excellent after-sales support and a stable running condition, Yongxin Can making machine has achieved the trust of can makers. With years of research in the field, we've come up with an automatic UN Pail line. Closed drum making line. More details on making cans, welcome to visit our website.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is devoted to the design and production of tin can machinery. We now have high-speed main automatic machines such as 40/60cpm small circular general can line, 30/50cpm smaller rectangular can line, 30cpm conical can line, seaming machines. Beyond the domestic market our products are also exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and so on. We are an original manufacturer with many years of experience. We offer the latest technology, top-quality can machines and top after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is the ideal choice for making cans with our machines.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is certified with SGS, CE and other certificates for our automatic can seaming equipment, which includes square and round can bodies. We seaming machines, such as for small, automatic can body making machines, for automatic round and rectangular seaming machine as well as an automated paper can seaming machine and others, which are secured by independent intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Our professional sales team are waiting for your consultation.