A robust seal is paramountto the cut and thrust world of packaging. From preserving food freshness to protecting the integrity of beverages, making sure cosmetics remain in good shape or that pharmaceuticals are still potent when consumed - a properly sealed container is crucial for product quality and safety.

Now, this is where the revolutionary tin seamer machine comes into play, and so does the sensitive topic revolving around it - a type of instrument that deals in sealing your everyday home-based objects (bottles & cans made out of metals which can become hazardous if not properly sealed). This particular tool has gone through an elongated process but now assists us with accurate measurements by standardizing everything top avoid any harmful errors. This has thus become a revolution, by which replacing the old model of sealing containers with advanced technology enabled tin seamer machine.

The decision-making process when choosing the right can seaming machine seems to be overwhelming but this is a choice that could make or break you. Several important factors on which you should decide in order to help make an informed decision are:

Try how many cans they need to seal daily, and look for a device that has enough capacity you can use.

Can Variety: Various cans require different seaming method and machines. Check that you pick a unit suited to the size as well as sort of cans in operation at your establishment.

Speed: How fast of a machine you are using is crucial as this dictates the speed at which production can roll. Look for a can seamer machine that is pretty close to your requirement in how fast it seams the cans.

Friequency:Tougher means more use out of it which translates to money saving by not needing as much maintenance. Search for a well-made, heavy-duty machine.

What are the Dos and Don'ts of Maintaining Peak Performance of Your Tin Seamer Machine

In order for your tin seamer machine to function optimally and ensure that the sealing process is working effectively, maintenance should be done properly. So, if you want to keep your sewing machine in good running condition, here are a few tips from the experts.

Routine Seaming Rolls Inspection: The seaming rolls are vital parts of a machine. Lint Free Observe how they are working and clean them periodically to keep them running efficiently.

Lubricate failed components of the machine, oils can work wonders if properly and consistently applied to moving parts.

Regular Cleaning: Periodically clean the machine to prevent dirt and debris build-up, which might interfere with seaming.

Replace Worn Parts Sooner Than Later- Pay attention to worn parts, if your machine starts experiencing issues get in contact with a representative right away so you don't risk the chance of harming other aspects on your seamer jeopardizing quality straight seals.

There are quite a lot of different benefits that can come from accepting the usage of one top grade tin seamer machine. Potential advantages of investing in this:

Higher Error-Free Sealing: A standard double seam seaming machine is designed to provide an error-free and leakage-proof sealing all the time, hence there will be no contamination or product spoilage.

Increased Productivity: Thanks to the rapid seaming process, you can reduce any delays sealing cans and thus increase efforts result.

Advanced precision and accuracy : The latest machine ensures precise seaming outcomes, which generates consistent quality output eliminating chances of leaks or rejects.

Lesser Operating Costs: The new generation of tin seamer machines is built to reduce wastage, avoid machine downtime and save on long-term operating costs which directly translates into profits for your company.

It requires consistent dedication, patience as well as practice to excel in the art of seaming. So to help with the process of practice, here are a few strategies you can use.

Good Can Type Selection: Different cans require different seaming methods. Get the can that best suits your product.

Setting the machine: Set your can sealer for the size and type of cans that you are using so it gives a tight enough seal to keep air from getting in.

FINAL TIP SEAM PROCESS: Watch Every Seam, No Manual Touch - At this point keep watching seaming process and allow adjusting for the same.

Practice makes perfect: While a lot of us are going to go by the instructions and still end up blundering it completely, seaming is one skill that only gets better with time. Practice is key to refining your talent and getting those consistent results.

Claims Tin Seamer Machine - The Need of the Time for Businesses Adopting in to Tin Cans and ContainersA tin seamer machine has remained long now, a sought after asset what with the truckloads of uses within commercial interests. Choosing the right equipment instead, proper maintenance and tools for your technology to top quality seaming avoid lousy leaks in pouches maintain operational efficiency Be successful continually improving a competitive industry.

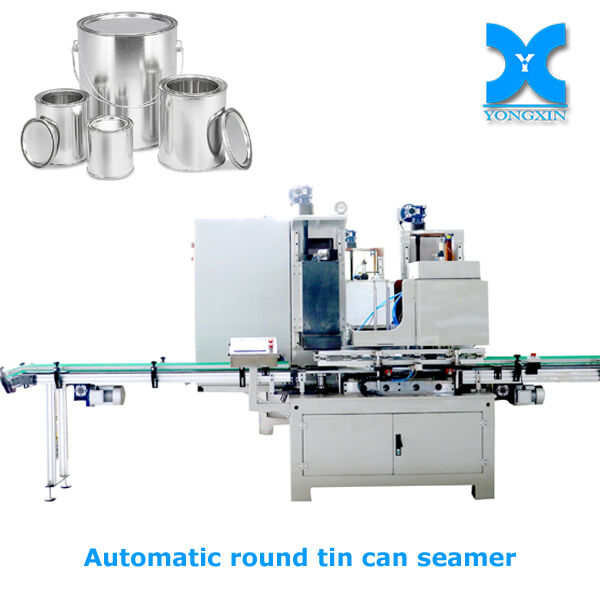

We are JIUJIANG YONGXIN CAN Equipment CO., LTD has been accredited by CE certification, SGS testing and tin seamer machine, for the products of automatic can seaming machine, automated round and square can body-making machines. We also have more than 84 patents, like for automatic small rectangular can body making machines, for an automatic round and rectangular can seaming machine for a paper-based can seaming machines and others, which are protected by the independent intellectual rights of property. The company was categorized as an "high technological enterprise in the province of JIANGXI Province" in China.

We have a team of experts that tin seamer machine to assist customers in maintaining and use their machines correctly.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is devoted to the design and production of tin can machinery. We now have high-speed main automatic machines such as 40/60cpm small circular general can line, 30/50cpm smaller rectangular can line, 30cpm conical can line, tin seamer machine. Beyond the domestic market our products are also exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and so on. We are an original manufacturer with many years of experience. We offer the latest technology, top-quality can machines and top after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is the ideal choice for making cans with our machines.

With over 20 years of experience in can manufacturing, Jiujiang Yongxin Can Equipment tin seamer machine. We offer all types of can making machines both semi-automatic as well as automatic. They offer the best quality and service. Can sizes are 0.1L-25L for square and round cans, and can be used for food, paint as well as for general purpose. Yongxin can maker is well-known to can makers as a reliable and top-quality can maker. More details on making cans, welcome to visit our website.

Our professional sales team are waiting for your consultation.