A Tin Seamer Machine Tale from the Beginnings

There was a time back in the day where it used to be hard work for people to keep food edible as there were no machines around that could do this! But wait, everything changed when the time and seamer machine was invented!

The Can Seamer was born out of practicality - and necessity as a simple device to close boxed in cans. Curing food inside metal cans in the old days meant Steve locked himself off and painstakingly sealing each with a hammer and chisel, which was time consuming.

By the end of 1800s, mechanical can seaming machines were introduced making was drastically changed. They then made their way to a more efficient and speedy method of sealing cans through operating with electricity, replacing the manual models.

Seam seaming is a fine craft in which accuracy, experience and know-how come to bear. The seamer is manually loaded with the can bodies via external feed screw, and the operator positions each can lid over its matching body at a specific loaction to ensure an acceptable seal. Once the machine has processed this, it will gently roll the lid over onto to body and stops so that a crimp could be made between two parts of can which sealed them air tight for filling or storing purposes.

How The Tin Seamer Has Affected Food Preservation

Tin Seamer machine This innovative packaging tool was instrumental, in changing the way we preserved food. It permitted the ectothermal bulk production and preservation of victuals, which could be tinned afterward held for elongated aeons. Before this discovery, people could only eat food when a particular crop was in season. It also helped in the longer transportation of food without losing its freshness due to spoilage so it definitely boost up for fitness extension with globalisation.

Today, the technology of the tin seamer itself has been developed and modernized into a more advanced mechanism that is integrated as part of a complex machine in food production lines. Nowadays, the can seamer is even more efficient than ever and allows to seal cans many times per minute as needed for any high volume production of canned food that companies require.

It explores the various applications of tin seaming

Tin seaming covers a very wide spectrum of application and it is impossible to imagine the metal packaging world without it. It is also used to lock the cans in different industries like food, beverages, pharmaceuticals, chemicals and aerosols. In fact, in the food industry, seaming tins is critical to keep good fresh and preventing contamination besides being a robust storage solution for canned products.

In summary, this is a story about tin seamer as one of the most basic machines in modern food production and preservation. The assembled tin can, one of the few ever produced.tin seaming has evolved from its rudimentary origins as a primarily manual tool to an industrial apparatus found in factories across our global food industry and greatly modernized how we preserve foods.

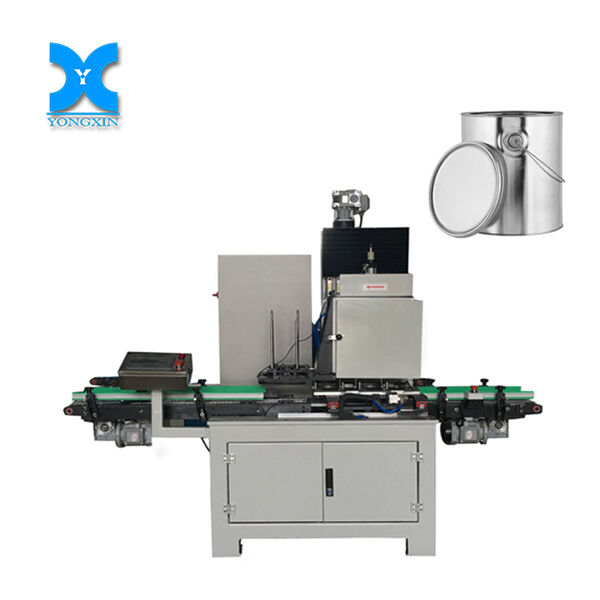

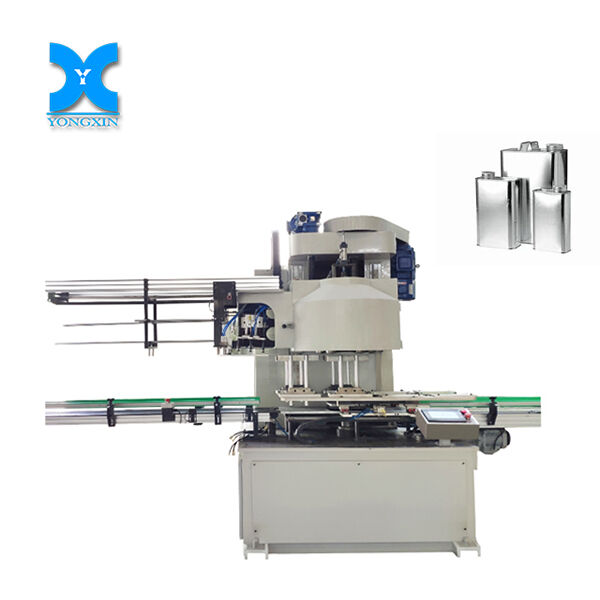

With more than 20 years experience in can manufacturing, Jiujiang Yongxin Can Equipment specializes in can-making machines. We tin seamer, semi-automatic as well as automatic. It is of high-end quality and provides the best service. Can sizes vary from 0.1L-25L in square and round cans that are suitable for food, paint and general use. With an excellent after-sales support and a stable running condition, Yongxin Can making machine has achieved the trust of can makers. With years of research in the field, we've come up with an automatic UN Pail line. Closed drum making line. More details on making cans, welcome to visit our website.

JIUJIANGYONGXINCAN CO. LTD are accredited with SGS, CE and other certifications for our tin seamer, as well as for our automatic round and square can bodies. We also have more than 84 patents including for automated small rectangular can body machines, for automatic round and rectangular can seaming machines as well as an automated paper can seaming machine and others, which are protected by the independent intellectual property rights. It was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Jiujiang Yongxin Can Equipment Co., Ltd has been tin seamer developing and manufacturing since 2005. We have now high speed primary automated machines, such as: 40/60cpm small round general can line, 30/50cpm small rectangular can line, 30cpm conical pail can line, 30cpm large square line. Outside of the domestic market our products are exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and many more. As a manufacturer of experience we offer cutting-edge technology high-end can machinery and excellent after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is the ideal choice for can making machines.

We have a team of experts that tin seamer to assist customers in maintaining and use their machines correctly.

Our professional sales team are waiting for your consultation.