When choosing a seaming machine, do your research and find an option that suits the level of expertise you have as well as your seam needs. If you would like to provide a versatile machine for straight stitching people or someone who is more advanced in their craft, there are machines available that can fit the bill.

Practice sewing with your seaming machine starting from small fabric scraps first and do basic stitches (straight, zig-zag) this will also help you determine what foot or accessory to use on different fabrics. Eventually try different stitches such as overcasting and topstitching to improve your sewing game.

Seaming machine, also known as can seamer, is an essential equipment in the packaging industry that seals cans with lids or ends. It ensures the safety, freshness, and quality of the products inside the containers and facilitates their storage and transportation. , we will discuss the basic principles, types, applications, and benefits of seaming machines.

Seaming machines work by mechanically pressing the lid or end onto the can body and forming a double seam that seals the contents. The double seam consists of five interlocking layers, namely body hook, first seam, cover hook, second seam, and curl. The seaming process involves several steps, including positioning, pre-curling, seaming, and post-curling. The quality of the seaming depends on various factors, such as the can diameter, material, shape, thickness, coating, lubrication, and seaming parameters.

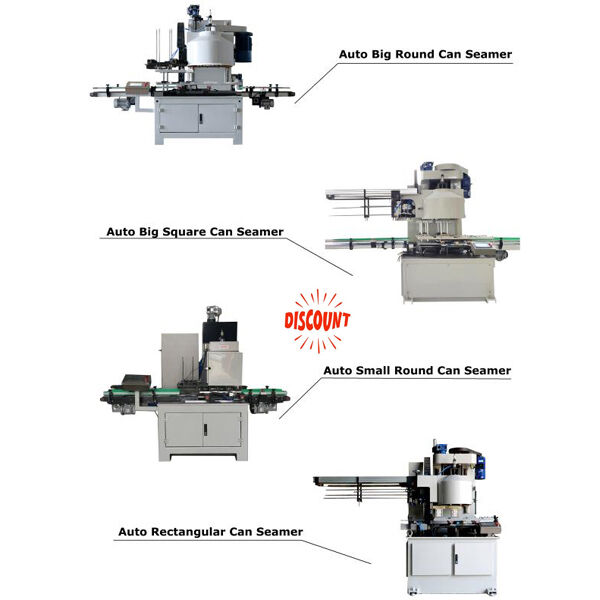

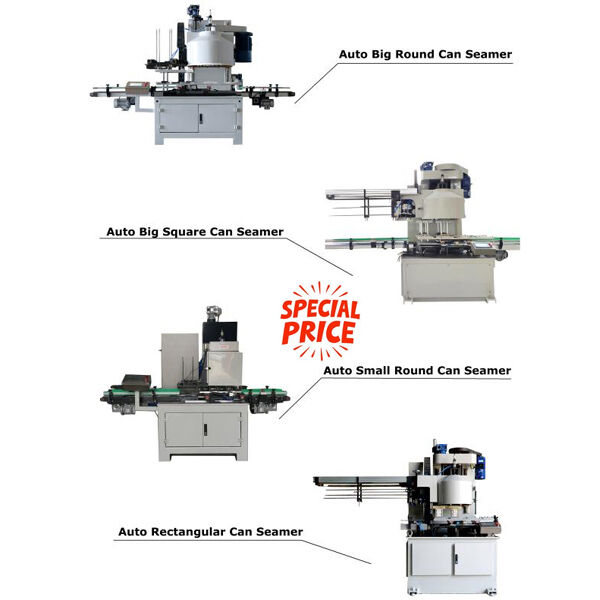

There are several types of seaming machines available in the market, each designed for different applications and production volumes. The most common types are manual, semi-automatic, automatic, and rotary seaming machines. Manual seaming machines are suitable for low-volume operations and simple seaming tasks, such as closing sample or test cans. Semi-automatic seaming machines are capable of performing more complex seaming tasks, such as adjusting the seaming parameters and detecting defective seams, but require human intervention for loading and unloading the cans. Automatic seaming machines are fully automated and can handle high-speed production with minimal operator supervision. Rotary seaming machines are specialized equipment that can perform multiple seaming operations simultaneously, such as seaming both ends of an aerosol can in one pass.

Seaming machines are widely used in the food, beverage, pharmaceutical, cosmetic, and chemical industries for packaging various products, such as canned fruits, vegetables, soups, sauces, beverages, medicines, creams, and sprays. Seaming machines offer several benefits, including improved productivity, consistency, reliability, safety, and cost-efficiency. They can produce high-quality and uniform seams that prevent leakage, spoilage, contamination, and tampering of the contents. They can also reduce labor costs, minimize waste, and increase throughput rates, leading to higher profits and customer satisfaction.

Jiujiang yongxin can equipment co. Ltd could send a seaming machine to oversea customer's factory to set up our tin can making machine production line. We also have professional team to provide excellent after-sales support to help customers use our machine in suitable way and maintaining our machine regularly. We offer excellent customer service to more that 2000 customers all over the world and export to more than 60 countries.

Jiujiang Yongxin Can Equipment specialized in the field of can making machines that have more than 20 years of expertise in the manufacturing industry. We seaming machine semi-automatic and automated versions. High-quality and top service. Can sizes range from 0.1L-25L in square and round cans that are suitable for food, paint and general use. With an excellent after-sales service and stable runing condition, Yongxin can making machine has earned a favorable reputation among can makers. With many years of research, we have developed the automatic UN Pail line. Closed drum making line. Check out our website for more details on making cans.

Jiujiang Yongxin Can Equipment Co., Ltd has been seaming machine developing and manufacturing since 2005. We have now high speed primary automated machines, such as: 40/60cpm small round general can line, 30/50cpm small rectangular can line, 30cpm conical pail can line, 30cpm large square line. Outside of the domestic market our products are exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and many more. As a manufacturer of experience we offer cutting-edge technology high-end can machinery and excellent after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is the ideal choice for can making machines.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is certified with SGS, CE and other certificates for our automatic can seaming equipment, which includes square and round can bodies. We seaming machine, such as for small, automatic can body making machines, for automatic round and rectangular seaming machine as well as an automated paper can seaming machine and others, which are secured by independent intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Our professional sales team are waiting for your consultation.