Canning in tin cans - how was it originally done?

The most important issues of the preservation in tin cans are utilized tin can seamer. The square can be sealed tightly making sure food kept inside stay fresh for a longer period using this special tool. Today we will look at how you can semi-auto tin can seamer easily use in your home,

Start by washing your cans and lids good in soapy water. Then boil them for about 10 actual minutes to make sure they are totally sterilized and safe.

After your cans are ready to go, you can start spooning in some liquid goodness until the top is freed up. Then snap the lids onto the cans and seal them with rubber bands to stop everything from splaying everywhere.

Next, you are going to load your cans into the seamer. Ensure the lid is properly positioned before you advance to next step. You will need to adjust the seamer settings so the pressure and speed at which it operates is just right. Finally, hit the pedal to start sealing you cans.

After the seaming process is over take them out of the system and label according to what has went inside. That way you will always know what good things are waiting for you when the need should arise.

Tin Can Closings Tin can seamers are also used in your home cooking areas and mechanical services as they assist to maintain food fresh. Learning the proper way on how to seal canned foods will guarantee that your favorite pantry staples remain tasty and every ready for you in times of hunger.

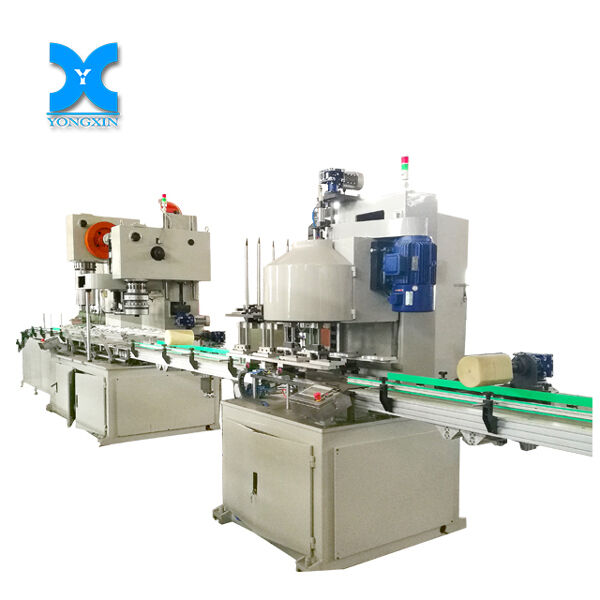

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is tin can seamer and manufacture of tin can equipment. Today, we have high-speed main automatic machines such as 40/60cpm small round general line for cans, 30/50cpm small rectangular can line, 30cpm conical can line, 30cpm big square can line. Our products are shipped not just to the local market, but also to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with many years of experience. We provide advanced technology, high-quality can equipment and top after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is your top choice for making cans with our machines.

Jiujiang yongxin can equipment co. Ltd could send a tin can seamer to visit our overseas customer's factory to install our Tin Can Making Machine production line. We have a professional team to provide a good after-sales service to assist customers in using our equipment in a way that is suitable and also to keep our machine in good condition regularly. We offer excellent customer service to more than 2000customers around the world. We also export to more than 60 countries.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is certified with SGS, CE and other certificates for our automatic can seaming equipment, which includes square and round can bodies. We tin can seamer, such as for small, automatic can body making machines, for automatic round and rectangular seaming machine as well as an automated paper can seaming machine and others, which are secured by independent intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Jiujiang Yongxin Can Equipment tin can seamer that have more than 20 years of experience in the can manufacturing industry. Provide all kinds of can making machines in semi-automatic and automated versions. High-quality and top service. Can sizes vary from 0.1L-25L in round and square cans for food, paint and general use. With good after sales service and reliable running conditions, Yongxin Can making machine has enjoyed a favorable reputation among can makers. With years of study we've developed the automatic UN Pail line. Closed drum making line. Visit our website for more details on making cans.

Our professional sales team are waiting for your consultation.