You are simply fond of tin cans and the treasures inside them. Tin cans are one of the crucial preservation means aside from those intended to make food cool and aseptically sealable. Sealing cans that have nothing in them is more complex than something converted into sounds. This is where the genius invention of tin can sealing machine comes in.

Tightening the lids one at a time is work-intensive and costly enough to make it uneconomical with tinplate. In reaction to this, many businesses now utilize electronic tin sealing machines. This machine has made the work of can sealing extremely simple, and now we are able to do these things in a faster way.

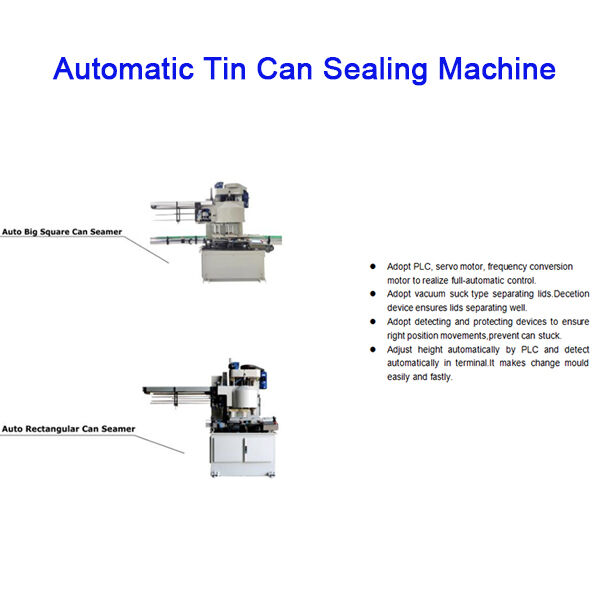

The technological wonder of the automatic tin can sealing machine will be able to seal that jar just as well, if not better than any human, all without breaking a sweat. So let get into it in this new breakthrough machine. The machine is broken into two primary bits; a lid feeder and the seamer that seals up those cans very tight in order to keep everything just as fresh inside, but keep you safe while its there.

Over the seamer a special roller is installed which called chuck through it this lids comes on top of can properly and lid feeder will put these in place.

An automatic tin can sealing machine will make it possible for any company to mass produce all kinds of cans much faster and effectively. Companies are able to produce more and perhaps see even higher-revenue, profit numbers as a result.

The automatic tin can sealing machine is able to seam up to 60 cans in a minute. Now, how many countless numbers of cans you can close with this machine in an hour or a day or year?

Another excellent example of human creativity is the automated tin can sealer which significantly facilitates and accelerates the sealing process. Food Industry: They save time and resources of businesses keeping preserved goods fresh and in good quality. Next time you open that can and savour the sweetness of heaven, think about this wonderful contraption which kept your delight fresh as ever!

The automatic tin can sealer machine is a marvellous example of innovative technological advancements. This machinery can do miracle of sealing that gan very completely & neatly, with just a push on outer button.

The Working Of The Machine It inculcates two basic unit one is Lid Feeder and other as Seamer, this machine rapidly seal cans together. The lids are has a lid feeder and the seamer marries can with lid ensuring all is sealed properly

There you have the Lid Feeder putting a lid on top of can. And, the seamer finally places simply a collar which is nothing but cylinder roller to press cans lid on right way.

An automatic tin sealer machine is so fast that it actually increase the productivity of industries. Businesses can make a number of cans in less period using this machine. That efficiency, of course, enables them to sell more and make money.

The machine is incredibly powerful, it can crimp up to 60 cans per minute! Think of how many cans that could seal in an hour, a day or even the week.

Knowledge concerning the absolutely automatic can seaming Which implies, machine able to doing it all, ranging from sticking these lids and as much as hermetically sealing completely empty cans.

For organizations, this level of automation is a huge win because it saves time and money When the machine did all of it, your local pharmacy had little reason to hire extra people just for filling them.

Tin Can Capping process is much irregular due to adoption of manual method, while automatic tin can sealer in this respect make the sealing regular in every way. To the machine, this means that it should always put on the lid and sealers fit onto uniformly every time.

Consistent -releasing food low energy cost (food stay fresh longer )

In conclusion, automatic tin can sealing machine is a time saver where the user only need to select what way of doing it. They help to apply a more lean, effective and suitable solution for businesses that want time saving, cost-efficiency measuring as well experience consistency results in the food industry. It is what kept beyond fresh. So the next time you gobble away on that canned culinary masterpiece, just remember which awesome little contraption caused it to remain inside there!

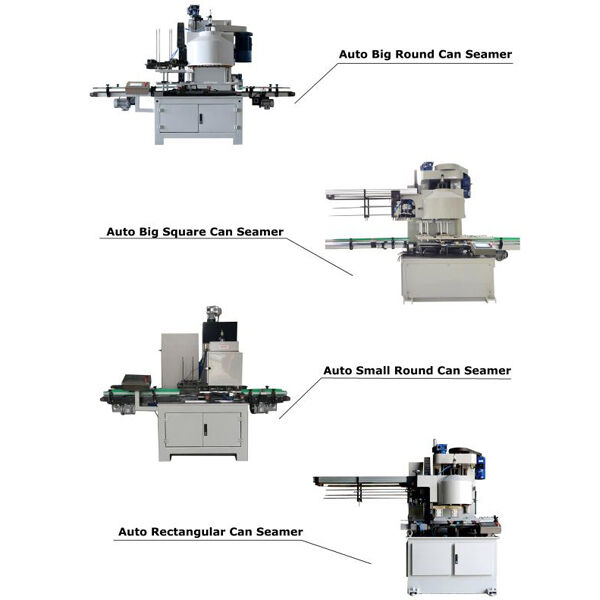

Jiujiang Yongxin Can Equipment Co., Ltd has been devoted to Tin can equipment development and manufacturing since 2005. We have high-speed automatic machines, including the 40/60cpm general small round can line; automatic tin can sealing machine; 30cpm pail machine line and 30cpm big can lines that are square. Our products are exported not only to the US market, but as well to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. As a pioneer manufacturer, we supply advanced technology with top quality can equipment and good after-sales service. You can select Jiujiang Yongxin Can Equipment Co., Ltd for your can making machines.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is certified with SGS, CE and other certificates for our automatic can seaming equipment, which includes square and round can bodies. We automatic tin can sealing machine, such as for small, automatic can body making machines, for automatic round and rectangular seaming machine as well as an automated paper can seaming machine and others, which are secured by independent intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Jiujiang yongxin can equipment co. Ltd can send a skilled technical experts to travel to our customer's factory to automatic tin can sealing machine. We also have a team of experts that can provide excellent after-sales services to assist customers using our machine in the right way and to maintain our machine regularly. We offer excellent customer service to more than 2000 customers throughout the world, and export to more than 60 countries.

Jiujiang Yongxin Can Equipment specialized in the field of making cans machines with more than 20 years of experience in the automatic tin can sealing machine. Provide all kinds of can making machine in semi-automatic and automated versions. With high quality and best service. Can sizes range from 0.1L-25L in square and round cans for paint, food and general use. With excellent after-sales service and reliable running conditions, Yongxin Can making machine has enjoyed the trust of can makers. With years of study in the field, we've come up with an automated UN Pail line. Closed drum making line. Check out our website for more details on making cans.

Our professional sales team are waiting for your consultation.